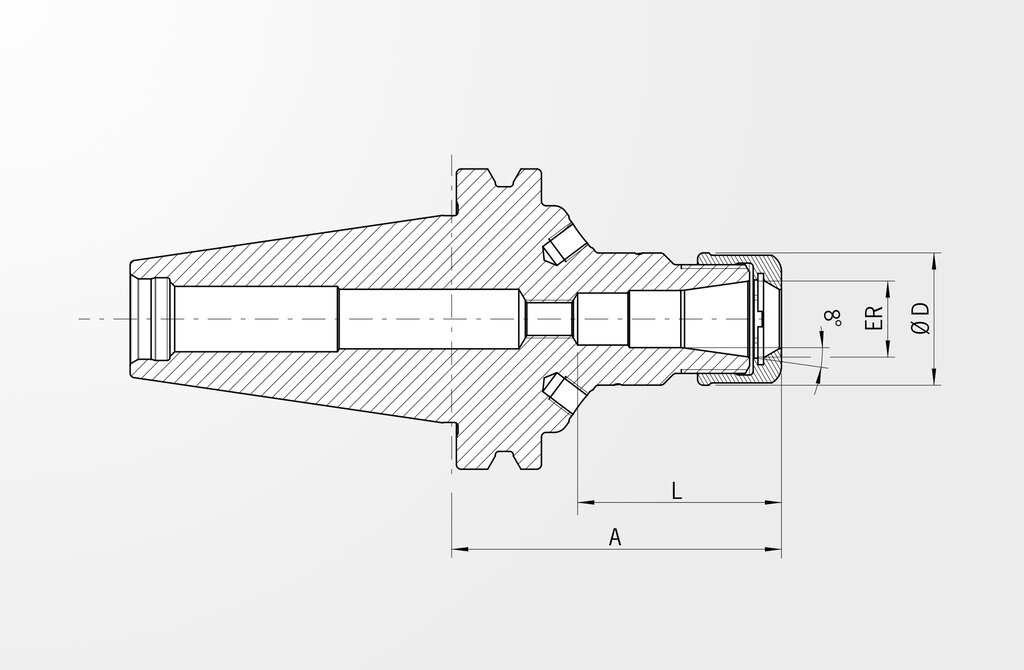

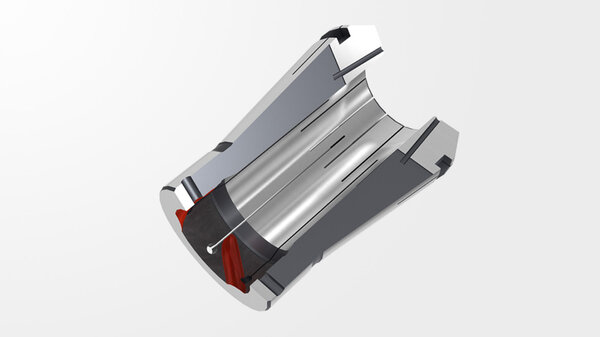

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets.

The High Presision Collet Chuck is designed for the highest cutting performance in High Speed machining. The optimized design with better construction and a special coated smooth locknut combines high rigidity with vibration dampening and noise-reducing features, giving more protection to machines, spindle and tools.