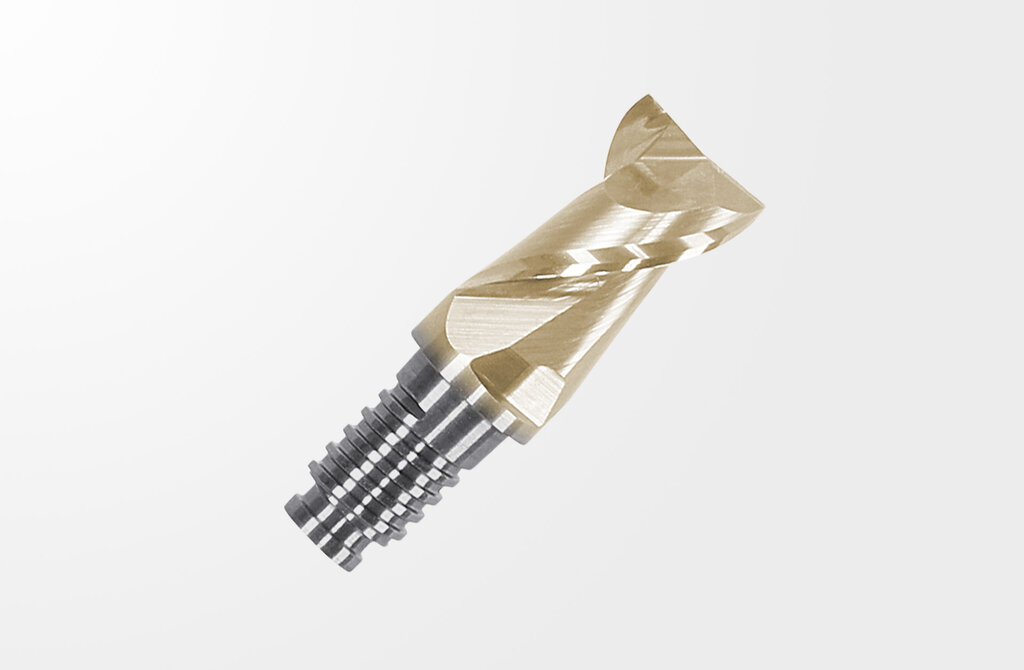

Solid carbide milling head with Duo-Lock interface for maximum stability, load capacity and runout accuracy.

Duo-Lock HAIMER MILL Alu Series - F4002MN Chamfer Coated

Modular milling head

Characteristics

Helix angle 41/43°

Helix angle 41/43°

Corner chamfer

Corner chamfer

Teeth 2

Teeth 2

Applications

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Ramping 45°

Ramping 45°

Slotting ball nose

Slotting ball nose

Side milling

Side milling

Drilling

Drilling

Areas of application-material

NF metals

NF metals

Duo-Lock HAIMER MILL Alu Series - F4002MN Chamfer Coated

Modular milling head

Quality pass

Fine balanced

Best length repeatability

- Coating for abrasive aluminum alloys

- Neck for higher cutting depth

- Center cutting

- Unequal helix

- Fine balanced

- Polished flute and relief

- Best length repeatability

- For roughing and finishing of aluminum

- Designed for high cutting parameters

- Suitable for drilling, ramping and slotting

Duo-Lock HAIMER MILL Alu Series - F4002MN Chamfer Coated

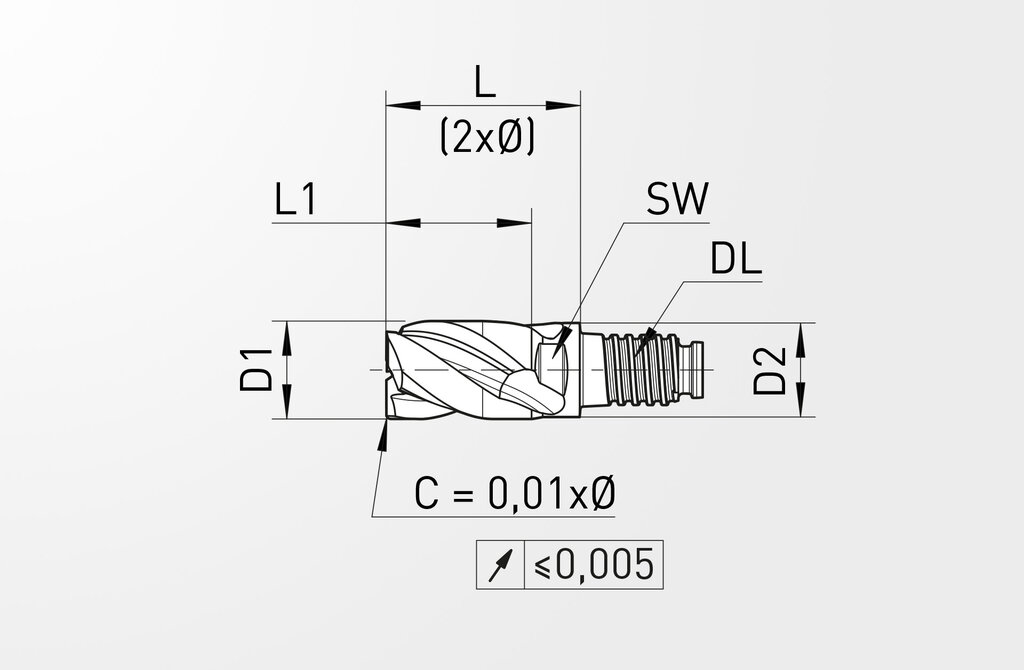

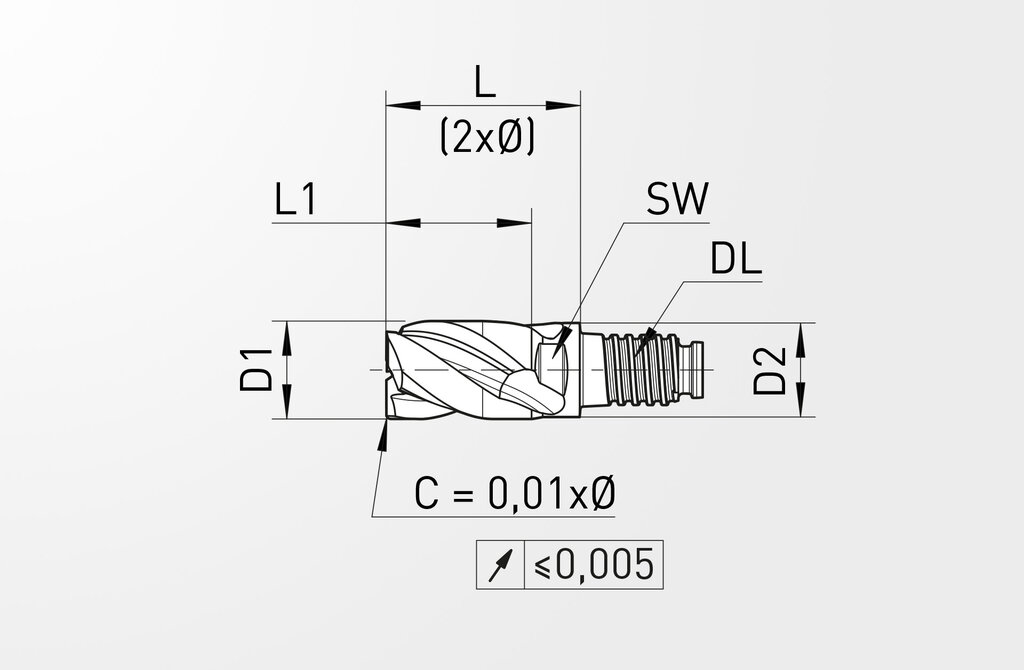

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Duo-Lock size | DL10 | |

| Cutting edge diameter | D1 | 10 mm |

| D1 Tolerance | h9 | |

| Number of cutting edges | Z | 2 |

| Corner design | C | |

| Chamfer size | C | 0,1 mm |

| Chamfer angle | W | 45 ° |

| Length of cutting edge | L1 | 15 mm |

| Head length | L | 20 mm |

| Neck diameter | D2 | 9,6 mm |

| Shank diameter | D | 7,5 mm |

| Shanklength | LS | 12,5 mm |

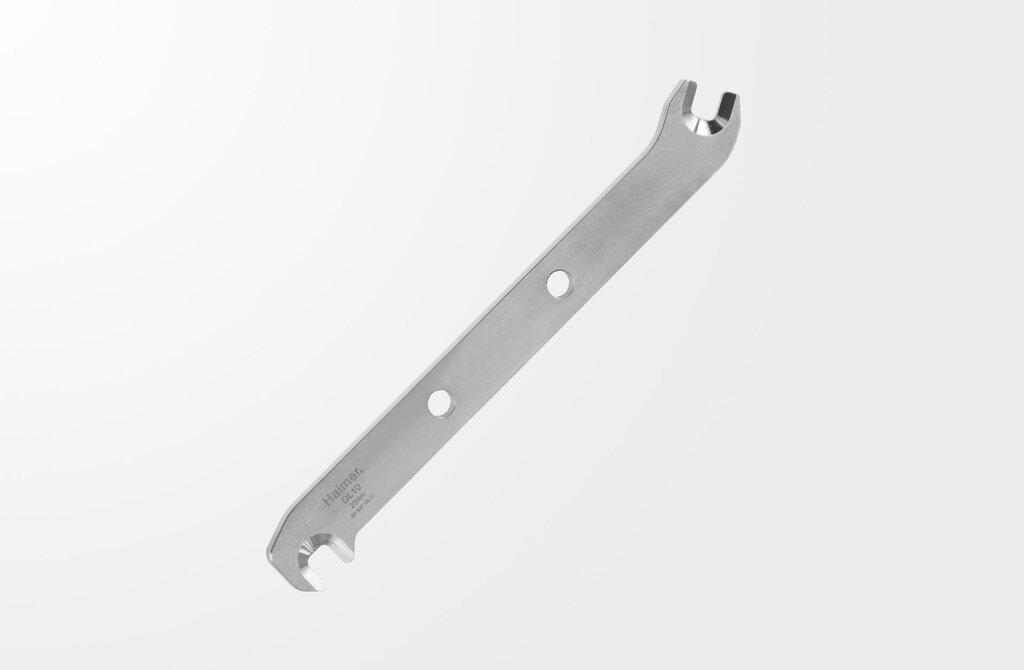

| Wrench size | 8 | |

| Type | L1 max, = 15 | |

| Helix angle | 41/43 ° | |

| HAIMER Material | D | |

| HAIMER Coating | C | |

| Torque | 20 Nm | |

| Cutting diameter | A1 | 10 mm |

| Peripheral effective cutting edge count | F21 | 2 |

| Corner chamfer width | G2 | 0,1 mm |

| Corner chamfer angle | G3 | 45 ° |

| Cutting edge length, max. | B2 | 15 mm |

| Overalllength | B5 | 32,5 mm |

| Head length | B6 | 20 mm |

| Neck diameter | A5 | 9,6 mm |

| Connection diameter, machine side | C3 | 7,5 mm |

| Shanklength | C4 | 12,5 mm |

| Helix angle | F4 | 42 ° |

| Mass (weight) | D7 | 0,021 kg |

| Standard number of properties layout | NSM | DIN4000-82 |

| Corner design | F72 | 2 - |

| Usable length | B4 | 20 mm |

| Protruding length | B3 | 20 mm |

| Functional length | B71 | 20 mm |

| Connection code type machine side | C11 | SAH |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 8 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0100 |

| mill tool type ISO | D11 | H |

| Hand | F1 | R |

| flute helix hand | F3 | R |

| face effective cutting edge count | F22 | 2 - |

| cutting edge centre count | F27 | 1 - |

| grade manufacturer's designation | H3 | VHM |

| Coating | H5 | C |

| Cutting tool type | H4 | H |

| grade standard designation, main application | H11 | HC |

| Company identification | J3 | HAI |

| interface code to machine side | J6 | SAH01000185 |

| machining process | J8 | FNB |

| Weight | WT | 0,021 kg |

Characteristics

Helix angle 41/43°

Helix angle 41/43°

Helix angle 41/43°

Helix angle 41/43°

Corner chamfer

Corner chamfer

Corner chamfer

Corner chamfer

Teeth 2

Teeth 2

Teeth 2

Teeth 2

Applications

- For roughing and finishing of aluminum

- Designed for high cutting parameters

- Suitable for drilling, ramping and slotting

AREAS OF APPLICATION - MATERIAL

MAIN AREA OF APPLICATION

NF metals

N

Aluminium and other non-ferrous metals, non ferrous materials

Operations

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Ramping 45°

Ramping 45°

Slotting ball nose

Slotting ball nose

Side milling

Side milling

Drilling

Drilling

Cooling

Emulsion

Emulsion

Cold air

Cold air

Dry machining

Dry machining

Cutting Data

Duo-Lock HAIMER MILL Alu Series - F4002MN Chamfer Coated

Description

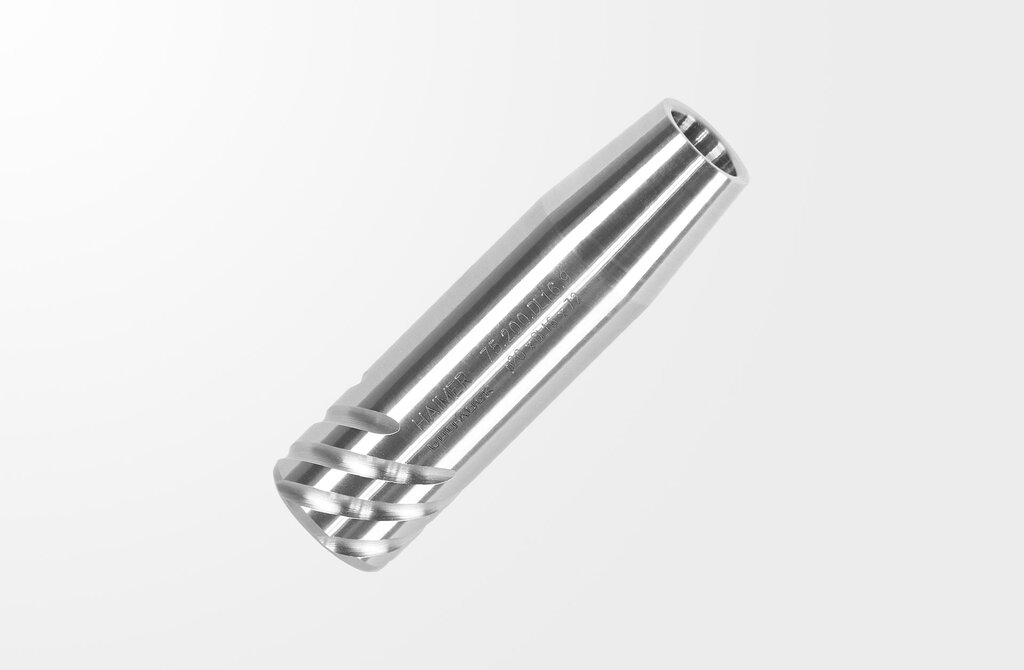

Duo-Lock HAIMER MILL Alu Series - F4002MN Chamfer Coated

Modular milling head

Quality pass

Fine balanced

Best length repeatability

Solid carbide milling head with Duo-Lock interface for maximum stability, load capacity and runout accuracy.

- Coating for abrasive aluminum alloys

- Neck for higher cutting depth

- Center cutting

- Unequal helix

- Fine balanced

- Polished flute and relief

- Best length repeatability

- For roughing and finishing of aluminum

- Designed for high cutting parameters

- Suitable for drilling, ramping and slotting

Technical specifications

Duo-Lock HAIMER MILL Alu Series - F4002MN Chamfer Coated

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Duo-Lock size | DL10 | |

| Cutting edge diameter | D1 | 10 mm |

| D1 Tolerance | h9 | |

| Number of cutting edges | Z | 2 |

| Corner design | C | |

| Chamfer size | C | 0,1 mm |

| Chamfer angle | W | 45 ° |

| Length of cutting edge | L1 | 15 mm |

| Head length | L | 20 mm |

| Neck diameter | D2 | 9,6 mm |

| Shank diameter | D | 7,5 mm |

| Shanklength | LS | 12,5 mm |

| Wrench size | 8 | |

| Type | L1 max, = 15 | |

| Helix angle | 41/43 ° | |

| HAIMER Material | D | |

| HAIMER Coating | C | |

| Torque | 20 Nm | |

| Cutting diameter | A1 | 10 mm |

| Peripheral effective cutting edge count | F21 | 2 |

| Corner chamfer width | G2 | 0,1 mm |

| Corner chamfer angle | G3 | 45 ° |

| Cutting edge length, max. | B2 | 15 mm |

| Overalllength | B5 | 32,5 mm |

| Head length | B6 | 20 mm |

| Neck diameter | A5 | 9,6 mm |

| Connection diameter, machine side | C3 | 7,5 mm |

| Shanklength | C4 | 12,5 mm |

| Helix angle | F4 | 42 ° |

| Mass (weight) | D7 | 0,021 kg |

| Standard number of properties layout | NSM | DIN4000-82 |

| Corner design | F72 | 2 - |

| Usable length | B4 | 20 mm |

| Protruding length | B3 | 20 mm |

| Functional length | B71 | 20 mm |

| Connection code type machine side | C11 | SAH |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 8 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0100 |

| mill tool type ISO | D11 | H |

| Hand | F1 | R |

| flute helix hand | F3 | R |

| face effective cutting edge count | F22 | 2 - |

| cutting edge centre count | F27 | 1 - |

| grade manufacturer's designation | H3 | VHM |

| Coating | H5 | C |

| Cutting tool type | H4 | H |

| grade standard designation, main application | H11 | HC |

| Company identification | J3 | HAI |

| interface code to machine side | J6 | SAH01000185 |

| machining process | J8 | FNB |

| Weight | WT | 0,021 kg |

Characteristics

Helix angle 41/43°

Helix angle 41/43°

Helix angle 41/43°

Helix angle 41/43°

Corner chamfer

Corner chamfer

Corner chamfer

Corner chamfer

Teeth 2

Teeth 2

Teeth 2

Teeth 2

Applications

Applications

- For roughing and finishing of aluminum

- Designed for high cutting parameters

- Suitable for drilling, ramping and slotting

AREAS OF APPLICATION - MATERIAL

MAIN AREA OF APPLICATION

NF metals

N

Aluminium and other non-ferrous metals, non ferrous materials

Operations

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Ramping 45°

Ramping 45°

Slotting ball nose

Slotting ball nose

Side milling

Side milling

Drilling

Drilling

Cooling

Emulsion

Emulsion

Cold air

Cold air

Dry machining

Dry machining

cutting data

Cutting Data

Duo-Lock HAIMER MILL Alu Series - F4002MN Chamfer Coated

All product variants

With the help of our filter you can refine your search by selecting attributes.

Filter

| Order No. | Chamfer size | Corner design | Cutting edge diameter | Duo-Lock size | HAIMER Coating | Head length | Length of cutting edge | Number of cutting edges | Shank diameter | Downloads | metric/ inch |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DL10F4002MN1000CDC | 0,1 mm | C | 10 mm | DL10 | C | 20 mm | 15 mm | 2 | 7,5 mm |

Download after registration

|

|

| DL12F4002MN1200CDC | 0,12 mm | C | 12 mm | DL12 | C | 24 mm | 18 mm | 2 | 8,5 mm |

Download after registration

|

|

| DL16F4002MN1600CDC | 0,16 mm | C | 16 mm | DL16 | C | 32 mm | 24 mm | 2 | 11,5 mm |

Download after registration

|

|

| DL20F4002MN2000CDC | 0,2 mm | C | 20 mm | DL20 | C | 40 mm | 30 mm | 2 | 14,5 mm |

Download after registration

|

Accessories

Haimer Care

The quality at Haimer is not only

by the product, but also by the

accompanying services.

Scope of service

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001