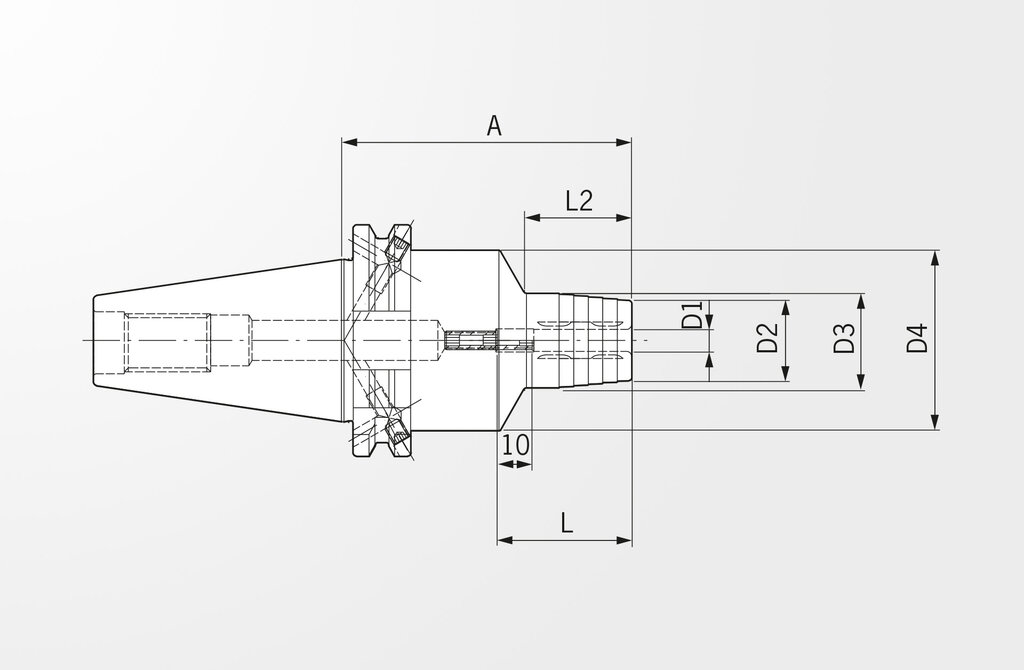

Standard hydraulic chuck, specially suitable for drilling operations and finishing milling operations.

Shank CAT50 according to ASME B5.50

Form AD/AF means central coolant supply and reclosable coolant channels at the collar.

Hydraulic chucks are a high-precision clamping technology. Their function is based on a hydraulic chamber that expands slightly during clamping, fixing the tool evenly and with high precision. They offer excellent runout accuracy and high vibration damping.