Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is designed for the highest cutting performance in High Speed machining. The optimized design combines high rigidity with vibration dampening, which protects the machine, spindle and tool.

Shrink Fit Chuck Power Shrink Chuck, Similar ASME B5.50 · CAT50 With Face Contact

- Additional support on the flange surface for more rigidity

- Highest cutting performance with higher spindle speeds, higher feeds and larger cutting dephts

- Shorter cycle times, higher machining accurancy

- Quiter running, therefore better surface quality and protection of tools, spindles and machines

- With threaded holes in order to balance with balancing screws

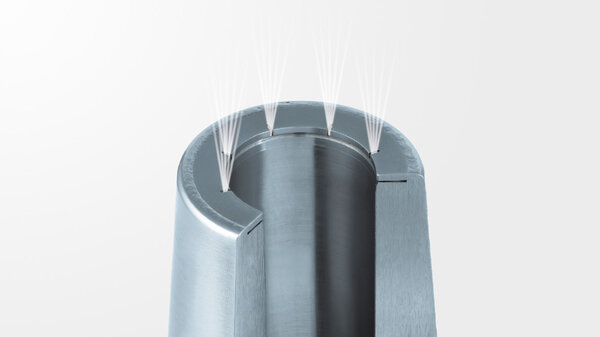

- Cool Jet coolant bores that can be sealed included

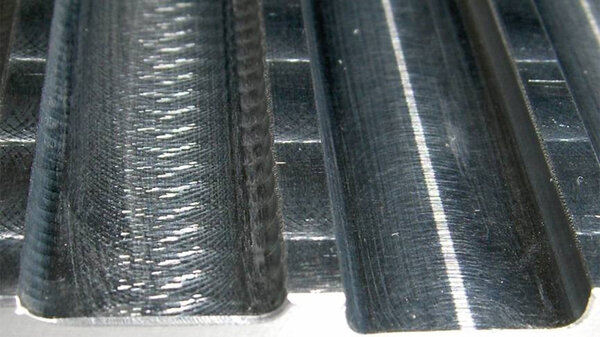

- High rigidity, slim at the tip, dampen vibrations

- Higher clamping forces

- Equally suited to High Speed and Heavy Duty machining

- Universal usage, saves space in tool magazine

- Compatible with Big-Plus spindles

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 3/4 inch |

| Length A | A | 3.15 inch |

| A-length version | short | |

| Diameter 2 | D2 | 1.772 inch |

| Length | L | 2.047 inch |

| Interface | CAT50 with Face Contact | |

| Upgrade | with Cool Jet | |

| Mass (weight) | D7 | 8.185 lbs |

| Weight | WT | 8.185 lbs |

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is designed for the highest cutting performance in High Speed machining. The optimized design combines high rigidity with vibration dampening, which protects the machine, spindle and tool.

- Additional support on the flange surface for more rigidity

- Highest cutting performance with higher spindle speeds, higher feeds and larger cutting dephts

- Shorter cycle times, higher machining accurancy

- Quiter running, therefore better surface quality and protection of tools, spindles and machines

- With threaded holes in order to balance with balancing screws

- Cool Jet coolant bores that can be sealed included

- High rigidity, slim at the tip, dampen vibrations

- Higher clamping forces

- Equally suited to High Speed and Heavy Duty machining

- Universal usage, saves space in tool magazine

- Compatible with Big-Plus spindles

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 3/4 inch |

| Length A | A | 3.15 inch |

| A-length version | short | |

| Diameter 2 | D2 | 1.772 inch |

| Length | L | 2.047 inch |

| Interface | CAT50 with Face Contact | |

| Upgrade | with Cool Jet | |

| Mass (weight) | D7 | 8.185 lbs |

| Weight | WT | 8.185 lbs |

| Order No. | A-length version | Clamping diameter | Interface | Length A | Upgrade | Downloads | metric/ inch |

|---|---|---|---|---|---|---|---|

| 50P.840.1/2Z.3 | short | 1/2 inch | CAT50 with Face Contact | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50P.840.1/2Z.37 | short | 1/2 inch | CAT50 with Face Contact | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50P.840.1/4Z.3 | short | 1/4 inch | CAT50 with Face Contact | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50P.840.1Z.3 | short | 1 inch | CAT50 with Face Contact | 3.937 inch | with Cool Jet |

Download after registration

|

|

| 50P.840.1Z.37 | short | 1 inch | CAT50 with Face Contact | 3.937 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50P.840.3/4Z.3 | short | 3/4 inch | CAT50 with Face Contact | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50P.840.3/4Z.37 | short | 3/4 inch | CAT50 with Face Contact | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50P.840.3/8Z.3 | short | 3/8 inch | CAT50 with Face Contact | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50P.840.5/16Z.3 | short | 5/16 inch | CAT50 with Face Contact | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50P.840.5/8Z.3 | short | 5/8 inch | CAT50 with Face Contact | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50P.840.5/8Z.37 | short | 5/8 inch | CAT50 with Face Contact | 3.15 inch | with Safe-Lock and Cool Jet |

|

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001