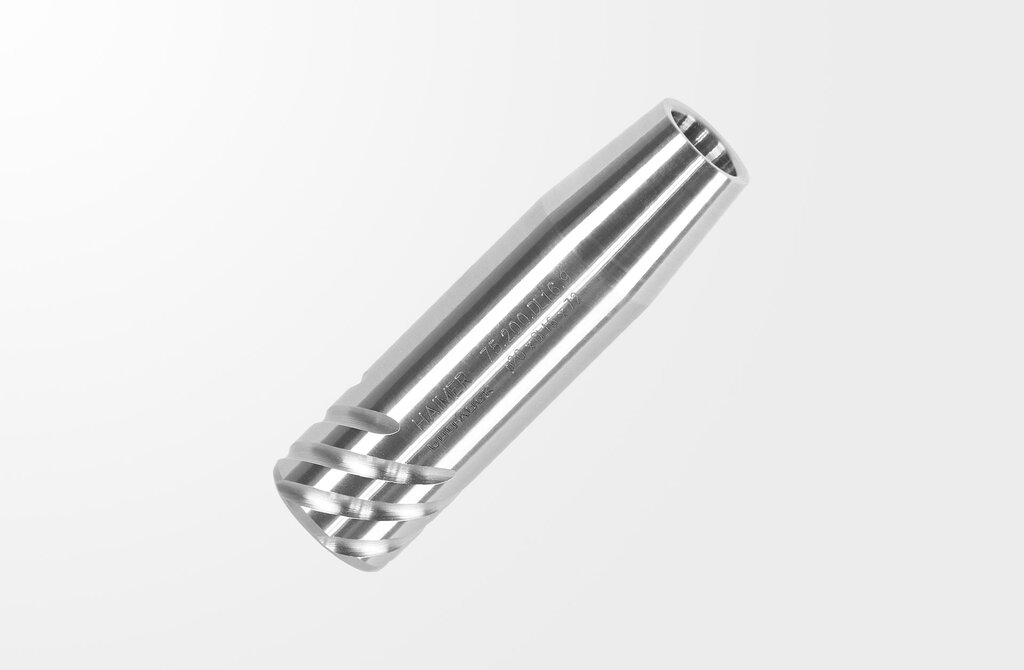

Solid carbide milling head with Duo-Lock interface for maximum stability, load capacity and runout accuracy.

Duo-Lock HAIMER MILL - E1016/18UK Chamfering End Mill

Modular milling head

Characteristics

Cone angle

Cone angle

Teeth 6

Teeth 6

Applications

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Chamfering

Chamfering

Areas of application-material

Steel

Steel

Stainless steel

Stainless steel

Cast iron

Cast iron

High temperature alloys and titanium alloys

High temperature alloys and titanium alloys

NF metals

NF metals

Hard materials

Hard materials

Duo-Lock HAIMER MILL - E1016/18UK Chamfering End Mill

Modular milling head

Quality pass

Fine balanced

Best length repeatability

Honed tip plan

- Cone angle 60/90/120°

- Honed tip plan

- Multifunctional tool

- Best length repeatability

- Straight fluted

- For almost all materials

- Suitable for fast chamfering and deburring

Duo-Lock HAIMER MILL - E1016/18UK Chamfering End Mill

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Duo-Lock size | DL20 | |

| Cutting edge diameter | D1 | 3/4 inch |

| D1 Tolerance | h6 | |

| Number of cutting edges | Z | 8 |

| Corner design | W | |

| Length of cutting edge | L1 | 0.171 inch |

| Head length | L | 0.984 inch |

| Neck diameter | D2 | 0.787 inch |

| Shank diameter | D | 0.571 inch |

| Shanklength | LS | 0.941 inch |

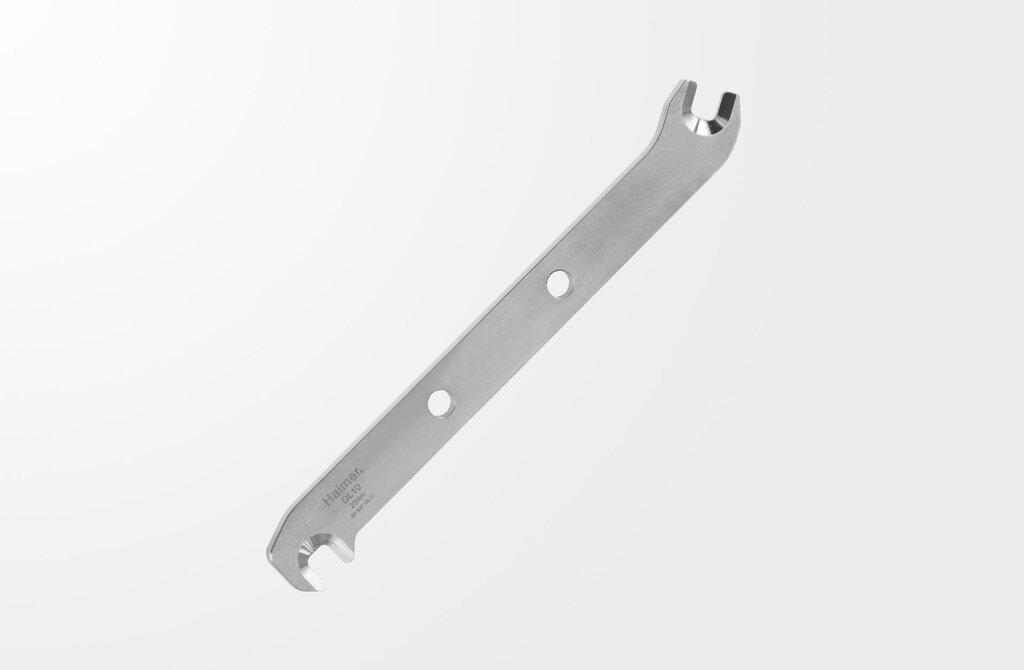

| Wrench size | 16 | |

| HAIMER Material | D | |

| HAIMER Coating | A | |

| Torque | 80 Nm | |

| Cutting diameter | A1 | 3/4 inch |

| Peripheral effective cutting edge count | F21 | 8 |

| Cutting edge length, max. | B2 | 0.171 inch |

| Overalllength | B5 | 1.925 inch |

| Head length | B6 | 0.984 inch |

| Neck diameter | A5 | 0.787 inch |

| Connection diameter, machine side | C3 | 0.571 inch |

| Shanklength | C4 | 0.941 inch |

| Helix angle | F4 | - ° |

| Mass (weight) | D7 | 0.287 lbs |

| Standard number of properties layout | NSM | DIN4000-82 |

| Protruding length | B3 | 0.984 inch |

| Functional length | B71 | 0.984 inch |

| Connection code type machine side | C11 | SAH |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 8 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0200 |

| Hand | F1 | R |

| flute helix hand | F3 | R |

| face effective cutting edge count | F22 | 8 - |

| grade manufacturer's designation | H3 | VHM |

| Coating | H5 | ALTIN |

| Cutting tool type | H4 | H |

| grade standard designation, main application | H11 | HC |

| Company identification | J3 | HAI |

| interface code to machine side | J6 | SAH02000185 |

| machining process | J8 | FEC |

| Weight | WT | 0.287 lbs |

Characteristics

Cone angle

Cone angle

Cone angle

Cone angle

Teeth 6

Teeth 6

Teeth 6

Teeth 6

Applications

- For almost all materials

- Suitable for fast chamfering and deburring

AREAS OF APPLICATION - MATERIAL

MAIN AREA OF APPLICATION

Steel

P

All types of steel and cast steel, with the exception of steel with an austenitic structure

FURTHER AREAS OF APPLICATION

Stainless steel

M

Stainless austenitic steel and austenitic-ferritic steel and cast steel

Cast iron

K

Grey cast iron, cast iron with spheroidal graphite, malleable cast iron, cast iron with vermicular graphite

High temperature alloys and titanium alloys

S

Heat resisting special alloys based on iron, nickel and cobalt, titanium and titanium alloys

NF metals

N

Aluminium and other non-ferrous metals, non ferrous materials

Hard materials

H

Hardened steel, hardened cast iron materials, chilled cast iron

Operations

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Chamfering

Chamfering

Cooling

Emulsion

Emulsion

Cold air

Cold air

Dry machining

Dry machining

Minimal lubrication

Minimal lubrication

Downloads

Register to get access to free downloads of CAD data (DXF and STP) on our product websites.

Cutting Data

Duo-Lock HAIMER MILL - E1016/18UK Chamfering End Mill

Description

Duo-Lock HAIMER MILL - E1016/18UK Chamfering End Mill

Modular milling head

Quality pass

Fine balanced

Best length repeatability

Honed tip plan

Solid carbide milling head with Duo-Lock interface for maximum stability, load capacity and runout accuracy.

- Cone angle 60/90/120°

- Honed tip plan

- Multifunctional tool

- Best length repeatability

- Straight fluted

- For almost all materials

- Suitable for fast chamfering and deburring

Technical specifications

Duo-Lock HAIMER MILL - E1016/18UK Chamfering End Mill

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Duo-Lock size | DL20 | |

| Cutting edge diameter | D1 | 3/4 inch |

| D1 Tolerance | h6 | |

| Number of cutting edges | Z | 8 |

| Corner design | W | |

| Length of cutting edge | L1 | 0.171 inch |

| Head length | L | 0.984 inch |

| Neck diameter | D2 | 0.787 inch |

| Shank diameter | D | 0.571 inch |

| Shanklength | LS | 0.941 inch |

| Wrench size | 16 | |

| HAIMER Material | D | |

| HAIMER Coating | A | |

| Torque | 80 Nm | |

| Cutting diameter | A1 | 3/4 inch |

| Peripheral effective cutting edge count | F21 | 8 |

| Cutting edge length, max. | B2 | 0.171 inch |

| Overalllength | B5 | 1.925 inch |

| Head length | B6 | 0.984 inch |

| Neck diameter | A5 | 0.787 inch |

| Connection diameter, machine side | C3 | 0.571 inch |

| Shanklength | C4 | 0.941 inch |

| Helix angle | F4 | - ° |

| Mass (weight) | D7 | 0.287 lbs |

| Standard number of properties layout | NSM | DIN4000-82 |

| Protruding length | B3 | 0.984 inch |

| Functional length | B71 | 0.984 inch |

| Connection code type machine side | C11 | SAH |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 8 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0200 |

| Hand | F1 | R |

| flute helix hand | F3 | R |

| face effective cutting edge count | F22 | 8 - |

| grade manufacturer's designation | H3 | VHM |

| Coating | H5 | ALTIN |

| Cutting tool type | H4 | H |

| grade standard designation, main application | H11 | HC |

| Company identification | J3 | HAI |

| interface code to machine side | J6 | SAH02000185 |

| machining process | J8 | FEC |

| Weight | WT | 0.287 lbs |

Characteristics

Cone angle

Cone angle

Cone angle

Cone angle

Teeth 6

Teeth 6

Teeth 6

Teeth 6

applications

Applications

- For almost all materials

- Suitable for fast chamfering and deburring

AREAS OF APPLICATION - MATERIAL

MAIN AREA OF APPLICATION

Steel

P

All types of steel and cast steel, with the exception of steel with an austenitic structure

FURTHER AREAS OF APPLICATION

Stainless steel

M

Stainless austenitic steel and austenitic-ferritic steel and cast steel

Cast iron

K

Grey cast iron, cast iron with spheroidal graphite, malleable cast iron, cast iron with vermicular graphite

High temperature alloys and titanium alloys

S

Heat resisting special alloys based on iron, nickel and cobalt, titanium and titanium alloys

NF metals

N

Aluminium and other non-ferrous metals, non ferrous materials

Hard materials

H

Hardened steel, hardened cast iron materials, chilled cast iron

Operations

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Chamfering

Chamfering

Cooling

Emulsion

Emulsion

Cold air

Cold air

Dry machining

Dry machining

Minimal lubrication

Minimal lubrication

Downloads

Downloads

Register to get access to free downloads of CAD data (DXF and STP) on our product websites.

Cutting Data

Cutting Data

Duo-Lock HAIMER MILL - E1016/18UK Chamfering End Mill

All product variants

With the help of our filter you can refine your search by selecting attributes.

Filter

| Order No. | Corner design | Cutting edge diameter | Duo-Lock size | HAIMER Coating | Head length | Length of cutting edge | Number of cutting edges | Shank diameter | Downloads | metric/ inch |

|---|---|---|---|---|---|---|---|---|---|---|

| DL10E1016UK1000W120DA | W | 0.394 inch | DL10 | A | 0.492 inch | 0.091 inch | 6 | 0.295 inch |

Download after registration

|

|

| DL10E1016UK1000W60DA | W | 0.394 inch | DL10 | A | 0.492 inch | 0.273 inch | 6 | 0.295 inch |

Download after registration

|

|

| DL10E1016UK1000W90DA | W | 0.394 inch | DL10 | A | 0.492 inch | 0.157 inch | 6 | 0.295 inch |

Download after registration

|

|

| DL10E1016UK3/8ZW120DA | W | 3/8 inch | DL10 | A | 0.492 inch | 0.086 inch | 6 | 0.295 inch |

|

|

| DL10E1016UK3/8ZW60DA | W | 3/8 inch | DL10 | A | 0.492 inch | 0.257 inch | 6 | 0.295 inch |

|

|

| DL10E1016UK3/8ZW90DA | W | 3/8 inch | DL10 | A | 0.492 inch | 0.148 inch | 6 | 0.295 inch |

|

|

| DL12E1016UK1/2ZW120DA | W | 1/2 inch | DL12 | A | 0.591 inch | 0.117 inch | 6 | 0.335 inch |

|

|

| DL12E1016UK1/2ZW60DA | W | 1/2 inch | DL12 | A | 0.591 inch | 0.351 inch | 6 | 0.335 inch |

Download after registration

|

|

| DL12E1016UK1/2ZW90DA | W | 1/2 inch | DL12 | A | 0.591 inch | 0.203 inch | 6 | 0.335 inch |

|

|

| DL12E1016UK1200W120DA | W | 0.472 inch | DL12 | A | 0.591 inch | 0.109 inch | 6 | 0.335 inch |

Download after registration

|

|

| DL12E1016UK1200W60DA | W | 0.472 inch | DL12 | A | 0.591 inch | 0.327 inch | 6 | 0.335 inch |

Download after registration

|

|

| DL12E1016UK1200W90DA | W | 0.472 inch | DL12 | A | 0.591 inch | 0.189 inch | 6 | 0.335 inch |

Download after registration

|

|

| DL16E1018UK1600W120DA | W | 0.63 inch | DL16 | A | 0.787 inch | 0.145 inch | 8 | 0.453 inch |

Download after registration

|

|

| DL16E1018UK1600W60DA | W | 0.63 inch | DL16 | A | 0.787 inch | 0.436 inch | 8 | 0.453 inch |

Download after registration

|

|

| DL16E1018UK1600W90DA | W | 0.63 inch | DL16 | A | 0.787 inch | 1/4 inch | 8 | 0.453 inch |

Download after registration

|

|

| DL16E1018UK5/8ZW120DA | W | 5/8 inch | DL16 | A | 0.787 inch | 0.144 inch | 8 | 0.453 inch |

|

|

| DL16E1018UK5/8ZW60DA | W | 5/8 inch | DL16 | A | 0.787 inch | 0.432 inch | 8 | 0.453 inch |

Download after registration

|

|

| DL16E1018UK5/8ZW90DA | W | 5/8 inch | DL16 | A | 0.787 inch | 1/4 inch | 8 | 0.453 inch |

|

|

| DL20E1018UK2000W120DA | W | 0.787 inch | DL20 | A | 0.984 inch | 0.182 inch | 8 | 0.571 inch |

Download after registration

|

|

| DL20E1018UK2000W60DA | W | 0.787 inch | DL20 | A | 0.984 inch | 0.545 inch | 8 | 0.571 inch |

Download after registration

|

|

| DL20E1018UK2000W90DA | W | 0.787 inch | DL20 | A | 0.984 inch | 0.315 inch | 8 | 0.571 inch |

Download after registration

|

|

| DL20E1018UK3/4ZW120DA | W | 3/4 inch | DL20 | A | 0.984 inch | 0.171 inch | 8 | 0.571 inch |

|

|

| DL20E1018UK3/4ZW60DA | W | 3/4 inch | DL20 | A | 0.984 inch | 0.513 inch | 8 | 0.571 inch |

Download after registration

|

|

| DL20E1018UK3/4ZW90DA | W | 3/4 inch | DL20 | A | 0.984 inch | 0.296 inch | 8 | 0.571 inch |

|

Accessories

Haimer Care

The quality at Haimer is not only

by the product, but also by the

accompanying services.

Scope of service

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001