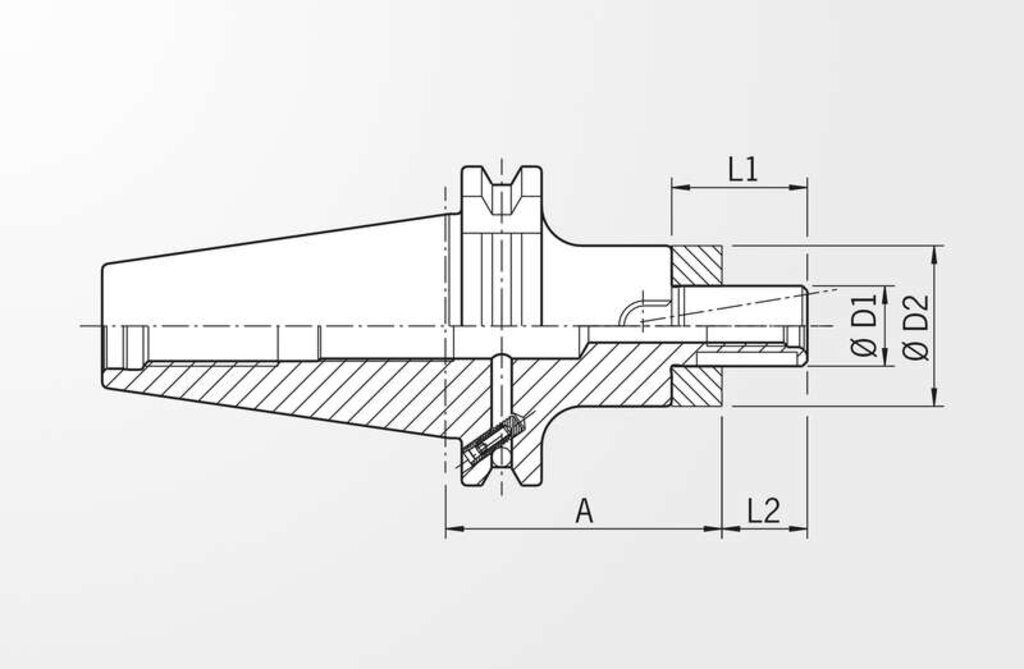

For clamping shell end mills DIN 841 and DIN 1880 as well as angular milling cutters DIN 842 and cutters DIN 1830.

According to DIN 6358 with taper SK40 form AD/AF DIN ISO 7388-1 (formerly DIN 69871).

Form AD/AF means: Central coolant supply and coolant channels on the collar which can be sealed again.

Combination Shell End Mill Arbor, DIN ISO 7388-1, SK40

(formerly DIN 69871)

Combination Shell End Mill Arbor, DIN ISO 7388-1, SK40

(formerly DIN 69871)

Quality pass

Chuck body fine balanced G2.5 at 22.000 rpm

All functional surfaces fine machined

Taper tolerance AT3

Coolant supply form AD/AF

Scope of Delivery

- With tightening bolt, driving ring and feather key

HAIMER TIP

For a constant and acurate cooling of te cutting tool we recommend coolant bores on the front side. (on request)

Combination Shell End Mill Arbor, DIN ISO 7388-1, SK40

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| A-length version | short | |

| Length A | A | 55 mm |

| Diameter 2 | D2 | 32 mm |

| Length 1 | L1 | 27 mm |

| Length 2 | L2 | 17 mm |

| Interface | SK40 | |

| Clamping diameter | D1 | 16 mm |

| Connection code style machine side | C15 | 5 |

| Connection code unit base machine side | C14 | 9 |

| Connection code form type machine side | C12 | 17 |

| Connection thread nominal size machine side | C13 | M16 |

| Connection size code machine side | C2 | 0400 |

| Connection code type machine side | C11 | SKG |

| Company identification | J3 | HAI |

| Mass (weight) | D7 | 1,090 kg |

| interface code to machine side | J6 | SKG04001795 |

| Connection code type machine side | CCTMS | SKG |

| Company identification | COMPC | HAI |

| Weight | WT | 1,090 kg |

Description

Combination Shell End Mill Arbor, DIN ISO 7388-1, SK40

(formerly DIN 69871)

Quality pass

Chuck body fine balanced G2.5 at 22.000 rpm

All functional surfaces fine machined

Taper tolerance AT3

Coolant supply form AD/AF

For clamping shell end mills DIN 841 and DIN 1880 as well as angular milling cutters DIN 842 and cutters DIN 1830.

According to DIN 6358 with taper SK40 form AD/AF DIN ISO 7388-1 (formerly DIN 69871).

Form AD/AF means: Central coolant supply and coolant channels on the collar which can be sealed again.

According to DIN 6358 with taper SK40 form AD/AF DIN ISO 7388-1 (formerly DIN 69871).

Form AD/AF means: Central coolant supply and coolant channels on the collar which can be sealed again.

Scope of Delivery

- With tightening bolt, driving ring and feather key

HAIMER TIP

For a constant and acurate cooling of te cutting tool we recommend coolant bores on the front side. (on request)

Technical specifications

Combination Shell End Mill Arbor, DIN ISO 7388-1, SK40

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| A-length version | short | |

| Length A | A | 55 mm |

| Diameter 2 | D2 | 32 mm |

| Length 1 | L1 | 27 mm |

| Length 2 | L2 | 17 mm |

| Interface | SK40 | |

| Clamping diameter | D1 | 16 mm |

| Connection code style machine side | C15 | 5 |

| Connection code unit base machine side | C14 | 9 |

| Connection code form type machine side | C12 | 17 |

| Connection thread nominal size machine side | C13 | M16 |

| Connection size code machine side | C2 | 0400 |

| Connection code type machine side | C11 | SKG |

| Company identification | J3 | HAI |

| Mass (weight) | D7 | 1,090 kg |

| interface code to machine side | J6 | SKG04001795 |

| Connection code type machine side | CCTMS | SKG |

| Company identification | COMPC | HAI |

| Weight | WT | 1,090 kg |

All product variants

With the help of our filter you can refine your search by selecting attributes.

Filter

| Order No. | A-length version | Clamping diameter | Interface | Length 1 | Length A | Downloads | metric/ inch |

|---|---|---|---|---|---|---|---|

| 40.340.16 | short | 16 mm | SK40 | 27 mm | 55 mm |

Download after registration

|

|

| 40.340.22 | short | 22 mm | SK40 | 31 mm | 55 mm |

Download after registration

|

|

| 40.340.27 | short | 27 mm | SK40 | 33 mm | 55 mm |

Download after registration

|

|

| 40.340.32 | short | 32 mm | SK40 | 38 mm | 60 mm |

Download after registration

|

|

| 40.340.40 | short | 40 mm | SK40 | 41 mm | 60 mm |

Download after registration

|

Accessories

Haimer Care

The quality at Haimer is not only

by the product, but also by the

accompanying services.

Scope of service

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001