Characteristics

Applications

Areas of application-material

Description

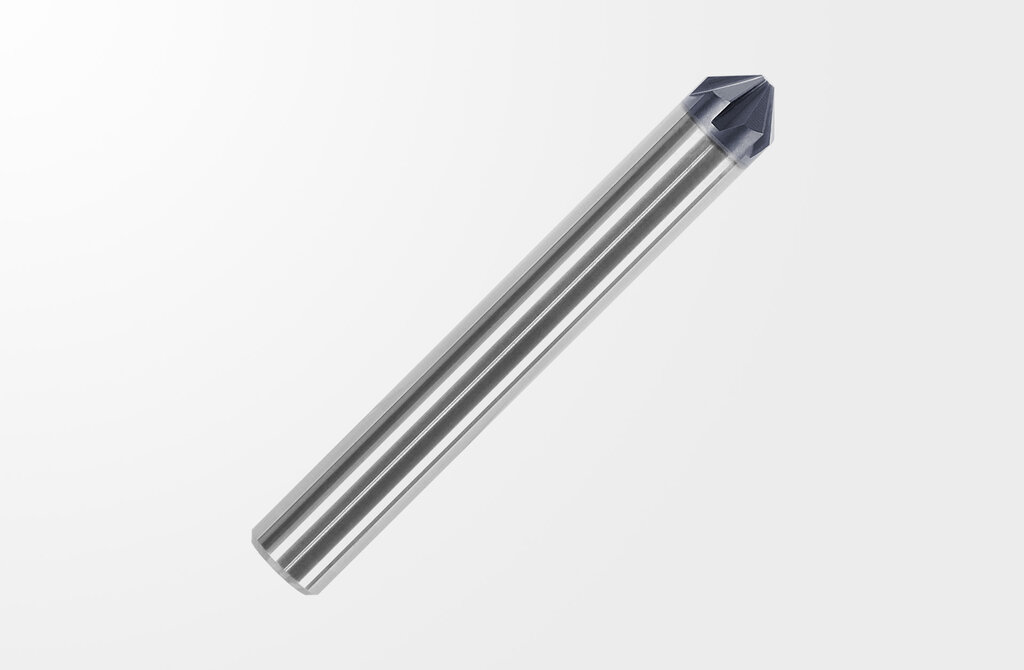

HAIMER MILL - E1014/16UN Chamfering End Mill

Solid carbide end mill

Quality pass

Honed tip plan

Multifunctional tool

Straight fluted

Chamfering end mill for chamfering of edges, grooves and holes

- Cone angle 60/90/120°

- Honed tip plan

- Multifunctional tool

- Straight fluted

- For almost all materials

- Suitable for fast chamfering and deburring

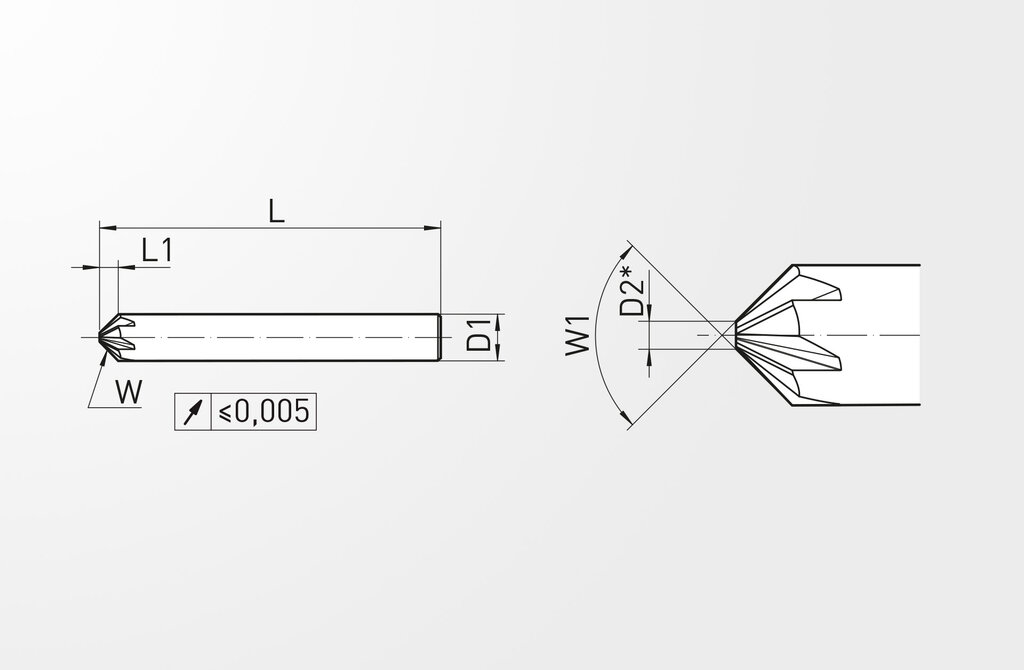

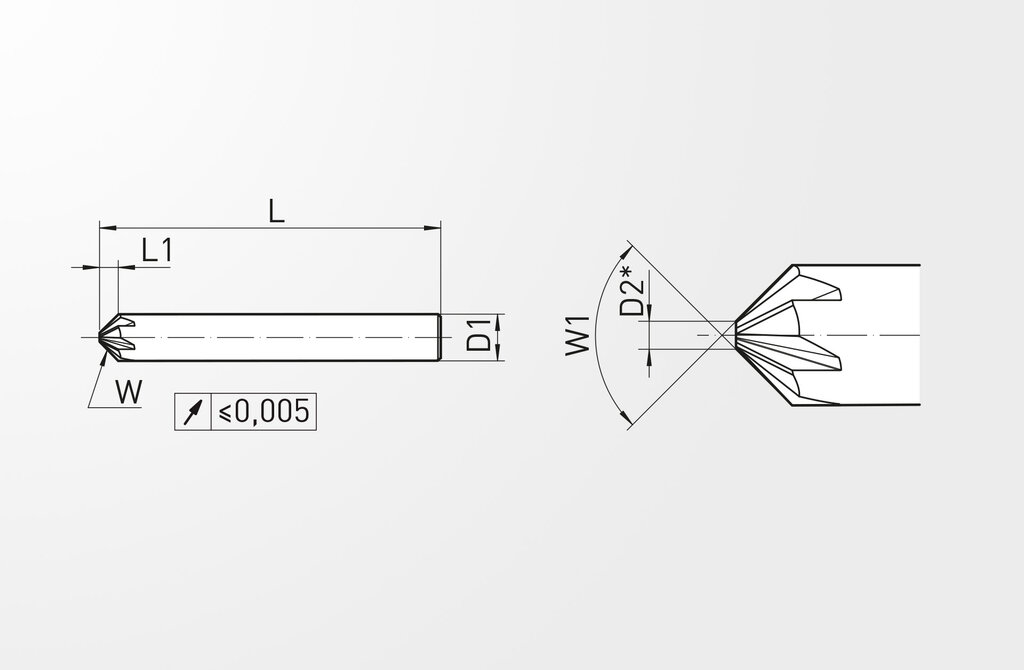

Technical specifications

Notice

Technical data subject to change without prior notice.

| Description | Norm: Haimer | Value: metric/inch |

|---|---|---|

| Cutting edge diameter | D1 | 4 inch / 0.157 inch |

| Number of cutting edges | Z | 4 |

| Corner design | W | |

| Chamfer size | C | 0,925 inch / 0.036 inch |

| Chamfer angle | W | 30 ° |

| Length of cutting edge | L1 | 0,925 inch / 0.036 inch |

| Overalllength | L | 51 inch / 2.008 inch |

| Neck diameter | D2 | 0,8 inch / 0.031 inch |

| Shank diameter | D | 4 inch / 0.157 inch |

| Shank version | Glattschaft | |

| HAIMER Material | D | |

| HAIMER Coating | A |

| Description | Norm: DIN 4000 | Value: metric/inch |

|---|---|---|

| Cutting diameter | A1 | 4 inch / 0.157 inch |

| Peripheral effective cutting edge count | F21 | 4 |

| Corner chamfer width | G2 | 0,925 inch / 0.036 inch |

| Corner chamfer angle | G3 | 30 ° |

| Cutting edge length, max. | B2 | 0,925 inch / 0.036 inch |

| Overalllength | B5 | 51 inch / 2.008 inch |

| Neck diameter | A5 | 0,8 inch / 0.031 inch |

| Connection diameter, machine side | C3 | 4 inch / 0.157 inch |

| Mass (weight) | D7 | 0,010 kg |

| Standard number of properties layout | NSM | DIN4000-82 |

| item style code | BLD | 2 |

| Connection code type machine side | C11 | ZYL |

| Connection code form type machine side | C12 | 01 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 40 |

| Hand | F1 | R |

| flute helix hand | F3 | N |

| face effective cutting edge count | F22 | 4 - |

| grade manufacturer's designation | H3 | D |

| Coating | H5 | A |

| Company identification | J3 | HAI |

| Description | Norm: ISO 13399 | Value: metric/inch |

|---|---|---|

| Weight | WT | 0,010 kg |

Characteristics

Cone angle

Teeth 4

Teeth 6

Straight shank (HA)

Applications

- For almost all materials

- Suitable for fast chamfering and deburring

AREAS OF APPLICATION - MATERIAL

MAIN AREA OF APPLICATION

Steel

All types of steel and cast steel, with the exception of steel with an austenitic structure

FURTHER AREAS OF APPLICATION

Stainless steel

Stainless austenitic steel and austenitic-ferritic steel and cast steel

Cast iron

Grey cast iron, cast iron with spheroidal graphite, malleable cast iron, cast iron with vermicular graphite

High temperature alloys and titanium alloys

Heat resisting special alloys based on iron, nickel and cobalt, titanium and titanium alloys

NF metals

Aluminium and other non-ferrous metals, non ferrous materials

Hard materials

Hardened steel, hardened cast iron materials, chilled cast iron

Operations

Feed direction (Side milling, Ramping, Drilling)

Chamfering

Cooling

Emulsion

Cold air

Dry machining

Minimal lubrication