Pull studs are an important link between machine and tool. The requirements concerning accuracy, rigidity and reliability are very high. Pull studs of minor quality not only decrease the performance of the machine, they are even a safety risk. A breaking pull stud might cause severe damage on machine and workpiece and even injuries on person

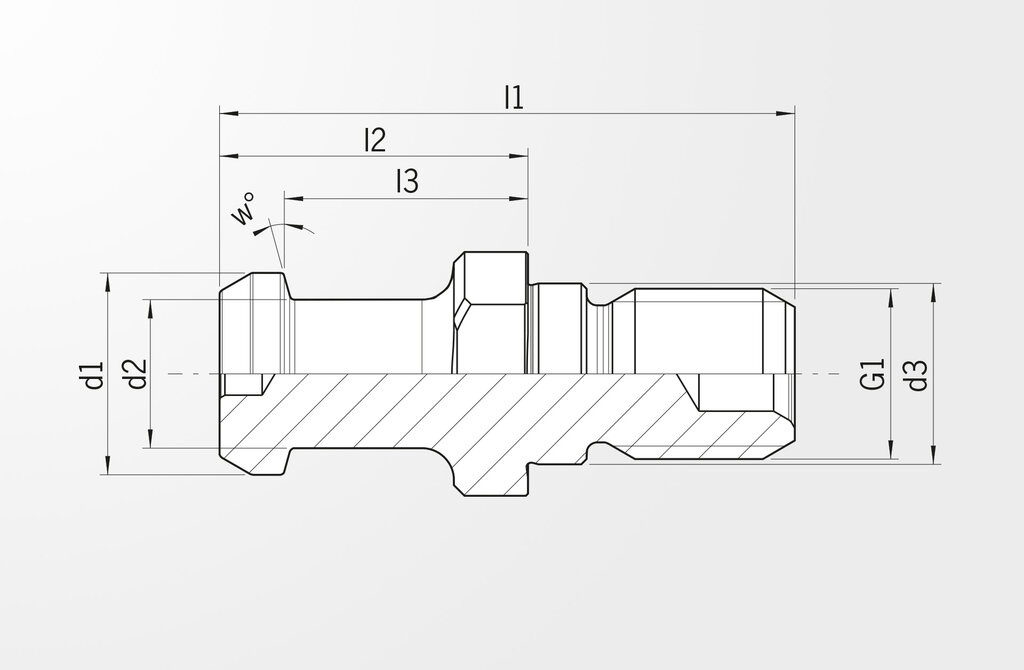

Pull stud JIS B 6339 without drill through

- Made of special steel with high rigidity

- Costly heat treatment in several steps

- Spots with highest stress tempered specifically

- High impact strength

- All functional surfaces fine finished after hardening.

- Highest security and reliability

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Version | CAT40 - 15° | |

| Diameter 1 | D1 | 3/4 inch |

| Diameter 2 | D2 | 0.551 inch |

| Diameter 3 | D3 | 0.669 inch |

| Length 1 | L1 | 2.126 inch |

| Length 2 | L2 | 1.142 inch |

| Length 3 | L3 | 0.906 inch |

| Thread 1 | g1 | M16 |

| Angle alpha | α | 15° |

Pull studs are an important link between machine and tool. The requirements concerning accuracy, rigidity and reliability are very high. Pull studs of minor quality not only decrease the performance of the machine, they are even a safety risk. A breaking pull stud might cause severe damage on machine and workpiece and even injuries on person

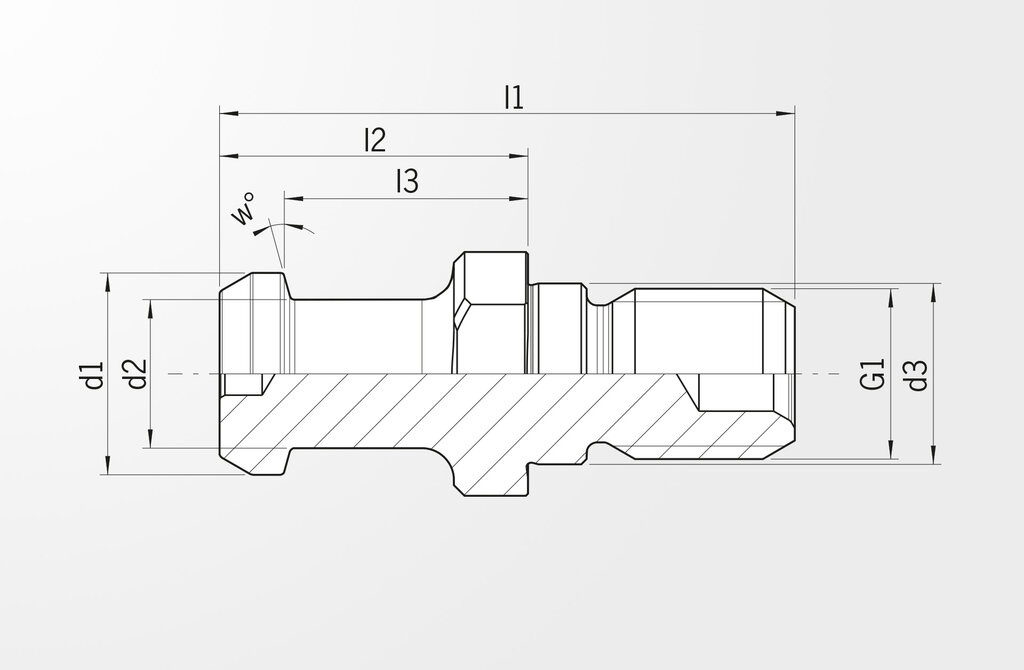

- Made of special steel with high rigidity

- Costly heat treatment in several steps

- Spots with highest stress tempered specifically

- High impact strength

- All functional surfaces fine finished after hardening.

- Highest security and reliability

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Version | CAT40 - 15° | |

| Diameter 1 | D1 | 3/4 inch |

| Diameter 2 | D2 | 0.551 inch |

| Diameter 3 | D3 | 0.669 inch |

| Length 1 | L1 | 2.126 inch |

| Length 2 | L2 | 1.142 inch |

| Length 3 | L3 | 0.906 inch |

| Thread 1 | g1 | M16 |

| Angle alpha | α | 15° |

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001