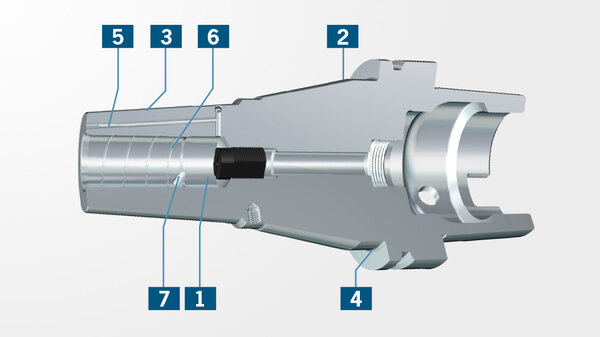

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

Power Shrink Chuck, DIN ISO 7388-1, SK50

(formerly DIN 69871)

Power Shrink Chuck, DIN ISO 7388-1, SK50

(formerly DIN 69871)

Quality pass

Chuck fine balanced G2.5 at 25.000 rpm

All functional surfaces fine machined

Taper tolerance AT3

Coolant supply form AD/AF

Cool Jet, can be sealed

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

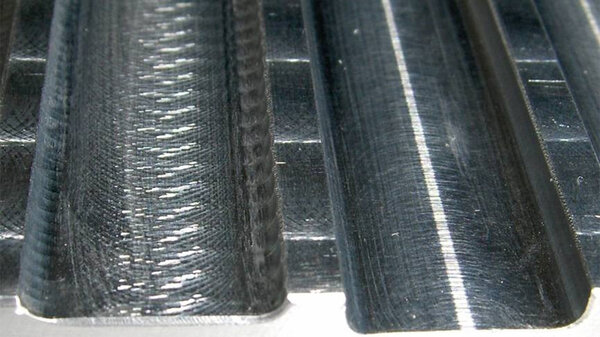

- Cool Jet bores that can be sealed included

- High rigidity

- Slim at the tip

- Dampen vibrations

- High clamping force

- Equally suited to high-speed manufacturing and heavy milling

- Universal usage, saves space in tool magazine

Scope of Delivery

- With backup screw

HAIMER TIP

For RPM higher 8000 U/min we recommend the optional cooling system Cool Flash. (on request)

Power Shrink Chuck, DIN ISO 7388-1, SK50

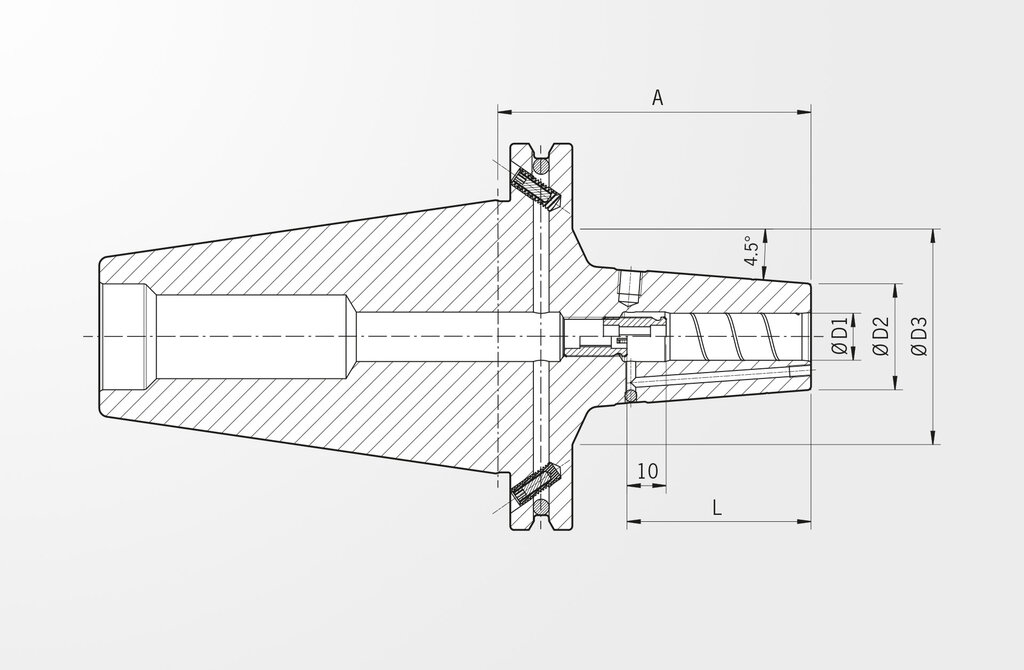

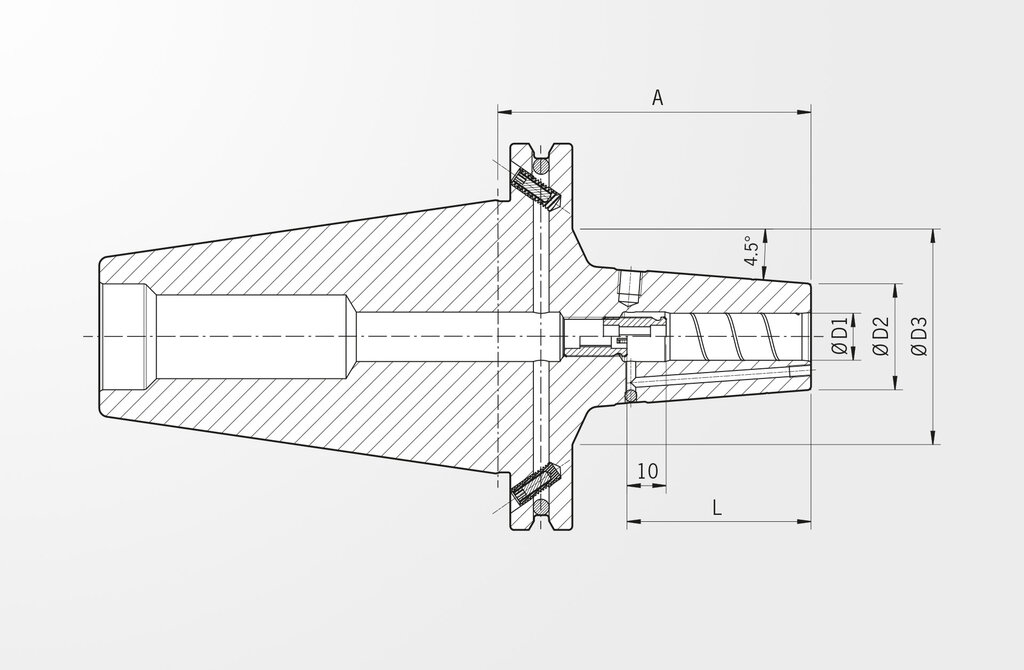

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 0.236 inch |

| Length A | A | 3.15 inch |

| A-length version | short | |

| Diameter 2 | D2 | 0.827 inch |

| Diameter 3 | D3 | 2.756 inch |

| Length | L | 1.417 inch |

| Interface | SK50 | |

| Upgrade | with Cool Jet | |

| Mass (weight) | D7 | 6.56 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | A1 | 1.132 inch |

| Body diameter 2 | A2 | 2.756 inch |

| Flange diameter | A4 | 3.839 inch |

| Interference diameter | A6 | 0.827 inch |

| Length body diameter 1 | B1 | 1.931 inch |

| Protruding length | B3 | 3.15 inch |

| Overall length | B4 | 7.156 inch |

| Taper angle | B51 | 4,5 ° |

| Taper angle 2 | B611 | 60 ° |

| Functional length | B71 | 1.732 inch |

| item style code | BLDf | 1 |

| item style code | BLD | 508145 |

| Connection code type machine side | C11 | SKG |

| Connection code form type machine side | C12 | 17 |

| Connection thread nominal size machine side | C13 | M24 |

| Connection code unit base machine side | C14 | 9 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0500 |

| Connection code type workpiece side | C51 | ZYL |

| Connection code form type workpiece side | C52 | 10 |

| Connection code unit base workpiece side | C54 | 1 |

| Connection code style workpiece side | C55 | 5 |

| Connection size code workpiece side | C6 | 0060 |

| Connection diameter min | C71 | 6 |

| Clamping length max. / nominal length | C81 | 1.417 inch |

| Clamping length, min., workpiece side | C82 | 1.024 inch |

| Balance grade | D5 | G2,5/25000 |

| Rotation speed, max | D6 | 25000 |

| Balancing device | D51 | 1 |

| Hand | E1 | N |

| coolant entry style code | H21 | 7 |

| coolant exit style code | H22 | 3 |

| Company identification | J3 | HAI |

| interface code to workpiece side | J4 | ZYL00600115 |

| interface code to machine side | J6 | SKG05001795 |

| Weight | WT | 6.56 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | BD1 | 1.132 inch |

| Flange diameter | DF | 3.839 inch |

| Interference diameter | DCINTF | 0.827 inch |

| Length body diameter 1 | LBD1 | 1.931 inch |

| Protruding length | LPR | 3.15 inch |

| Overall length | OAL | 7.156 inch |

| Taper angle | TA | 4,5 ° |

| Functional length | LF | 1.732 inch |

| Connection code type machine side | CCTMS | SKG |

| Connection code unit base workpiece side | CCUWS | 1 |

| Connection code style workpiece side | CCSWS | 5 |

| Connection size code workpiece side | CZCWS | 0060 |

| Connection diameter min | DCONN | 6 |

| Clamping length max. / nominal length | LSCX | 1.417 inch |

| Hand | HAND | N |

| coolant entry style code | CNSC | 7 |

| coolant exit style code | CXSC | 3 |

| Company identification | COMPC | HAI |

Description

Power Shrink Chuck, DIN ISO 7388-1, SK50

(formerly DIN 69871)

Quality pass

Chuck fine balanced G2.5 at 25.000 rpm

All functional surfaces fine machined

Taper tolerance AT3

Coolant supply form AD/AF

Cool Jet, can be sealed

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

The Power Shrink Chuck is the shrink fit chuck for highest machining capacity in high-speed manufacturing. The optimized design combines high rigidity with dampening vibrations, therefore giving more protection to machines, spindles and tools.

- Increased machining capacity due to higher spindle speed, higher feed and larger cutting depth

- Shorter processing times

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Higher machining accuracy

- With threaded holes in order to balance with balancing screws

- Cool Jet bores that can be sealed included

- High rigidity

- Slim at the tip

- Dampen vibrations

- High clamping force

- Equally suited to high-speed manufacturing and heavy milling

- Universal usage, saves space in tool magazine

Scope of Delivery

- With backup screw

HAIMER TIP

For RPM higher 8000 U/min we recommend the optional cooling system Cool Flash. (on request)

Technical specifications

Power Shrink Chuck, DIN ISO 7388-1, SK50

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 0.236 inch |

| Length A | A | 3.15 inch |

| A-length version | short | |

| Diameter 2 | D2 | 0.827 inch |

| Diameter 3 | D3 | 2.756 inch |

| Length | L | 1.417 inch |

| Interface | SK50 | |

| Upgrade | with Cool Jet | |

| Mass (weight) | D7 | 6.56 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | A1 | 1.132 inch |

| Body diameter 2 | A2 | 2.756 inch |

| Flange diameter | A4 | 3.839 inch |

| Interference diameter | A6 | 0.827 inch |

| Length body diameter 1 | B1 | 1.931 inch |

| Protruding length | B3 | 3.15 inch |

| Overall length | B4 | 7.156 inch |

| Taper angle | B51 | 4,5 ° |

| Taper angle 2 | B611 | 60 ° |

| Functional length | B71 | 1.732 inch |

| item style code | BLDf | 1 |

| item style code | BLD | 508145 |

| Connection code type machine side | C11 | SKG |

| Connection code form type machine side | C12 | 17 |

| Connection thread nominal size machine side | C13 | M24 |

| Connection code unit base machine side | C14 | 9 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0500 |

| Connection code type workpiece side | C51 | ZYL |

| Connection code form type workpiece side | C52 | 10 |

| Connection code unit base workpiece side | C54 | 1 |

| Connection code style workpiece side | C55 | 5 |

| Connection size code workpiece side | C6 | 0060 |

| Connection diameter min | C71 | 6 |

| Clamping length max. / nominal length | C81 | 1.417 inch |

| Clamping length, min., workpiece side | C82 | 1.024 inch |

| Balance grade | D5 | G2,5/25000 |

| Rotation speed, max | D6 | 25000 |

| Balancing device | D51 | 1 |

| Hand | E1 | N |

| coolant entry style code | H21 | 7 |

| coolant exit style code | H22 | 3 |

| Company identification | J3 | HAI |

| interface code to workpiece side | J4 | ZYL00600115 |

| interface code to machine side | J6 | SKG05001795 |

| Weight | WT | 6.56 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | BD1 | 1.132 inch |

| Flange diameter | DF | 3.839 inch |

| Interference diameter | DCINTF | 0.827 inch |

| Length body diameter 1 | LBD1 | 1.931 inch |

| Protruding length | LPR | 3.15 inch |

| Overall length | OAL | 7.156 inch |

| Taper angle | TA | 4,5 ° |

| Functional length | LF | 1.732 inch |

| Connection code type machine side | CCTMS | SKG |

| Connection code unit base workpiece side | CCUWS | 1 |

| Connection code style workpiece side | CCSWS | 5 |

| Connection size code workpiece side | CZCWS | 0060 |

| Connection diameter min | DCONN | 6 |

| Clamping length max. / nominal length | LSCX | 1.417 inch |

| Hand | HAND | N |

| coolant entry style code | CNSC | 7 |

| coolant exit style code | CXSC | 3 |

| Company identification | COMPC | HAI |

All product variants

With the help of our filter you can refine your search by selecting attributes.

Filter

| Order No. | A-length version | Clamping diameter | Interface | Length A | Upgrade | Downloads | metric/ inch |

|---|---|---|---|---|---|---|---|

| 50.440.06.3 | short | 0.236 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.06.37 | short | 0.236 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.08.3 | short | 0.315 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.08.37 | short | 0.315 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.10.3 | short | 0.394 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.10.37 | short | 0.394 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.12.3 | short | 0.472 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.12.37 | short | 0.472 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.14.3 | short | 0.551 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.14.37 | short | 0.551 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.16.3 | short | 0.63 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.16.37 | short | 0.63 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.18.3 | short | 0.709 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.18.37 | short | 0.709 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.20.3 | short | 0.787 inch | SK50 | 3.15 inch | with Cool Jet |

Download after registration

|

|

| 50.440.20.37 | short | 0.787 inch | SK50 | 3.15 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.440.25.3 | short | 0.984 inch | SK50 | 3.937 inch | with Cool Jet |

Download after registration

|

|

| 50.440.25.37 | short | 0.984 inch | SK50 | 3.937 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.442.06.3 | oversize (160 mm) | 0.236 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.08.3 | oversize (160 mm) | 0.315 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.10.3 | oversize (160 mm) | 0.394 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.12.3 | oversize (160 mm) | 0.472 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.12.37 | oversize (160 mm) | 0.472 inch | SK50 | 6.299 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.442.14.3 | oversize (160 mm) | 0.551 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.14.37 | oversize (160 mm) | 0.551 inch | SK50 | 6.299 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.442.16.3 | oversize (160 mm) | 0.63 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.16.37 | oversize (160 mm) | 0.63 inch | SK50 | 6.299 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.442.18.3 | oversize (160 mm) | 0.709 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.18.37 | oversize (160 mm) | 0.709 inch | SK50 | 6.299 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.442.20.3 | oversize (160 mm) | 0.787 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.20.37 | oversize (160 mm) | 0.787 inch | SK50 | 6.299 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.442.25.3 | oversize (160 mm) | 0.984 inch | SK50 | 6.299 inch | with Cool Jet |

Download after registration

|

|

| 50.442.25.37 | oversize (160 mm) | 0.984 inch | SK50 | 6.299 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.446.06.3 | ZG200 | 0.236 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.08.3 | ZG200 | 0.315 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.10.3 | ZG200 | 0.394 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.12.3 | ZG200 | 0.472 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.12.37 | ZG200 | 0.472 inch | SK50 | 7.874 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.446.14.3 | ZG200 | 0.551 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.14.37 | ZG200 | 0.551 inch | SK50 | 7.874 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.446.16.3 | ZG200 | 0.63 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.16.37 | ZG200 | 0.63 inch | SK50 | 7.874 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.446.18.3 | ZG200 | 0.709 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.18.37 | ZG200 | 0.709 inch | SK50 | 7.874 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.446.20.3 | ZG200 | 0.787 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.20.37 | ZG200 | 0.787 inch | SK50 | 7.874 inch | with Safe-Lock and Cool Jet |

Download after registration

|

|

| 50.446.25.3 | ZG200 | 0.984 inch | SK50 | 7.874 inch | with Cool Jet |

Download after registration

|

|

| 50.446.25.37 | ZG200 | 0.984 inch | SK50 | 7.874 inch | with Safe-Lock and Cool Jet |

Download after registration

|

Accessories

Haimer Care

The quality at Haimer is not only

by the product, but also by the

accompanying services.

Scope of service

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001