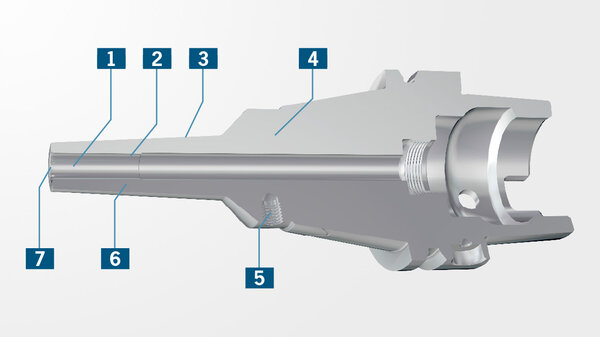

Shrink fit chuck suitable to all inductive shrink fit units.

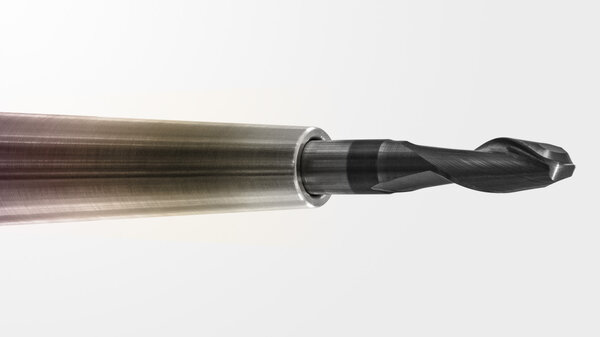

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

Power Mini Shrink Chuck extra slim, DIN 69893-1, HSK-A63

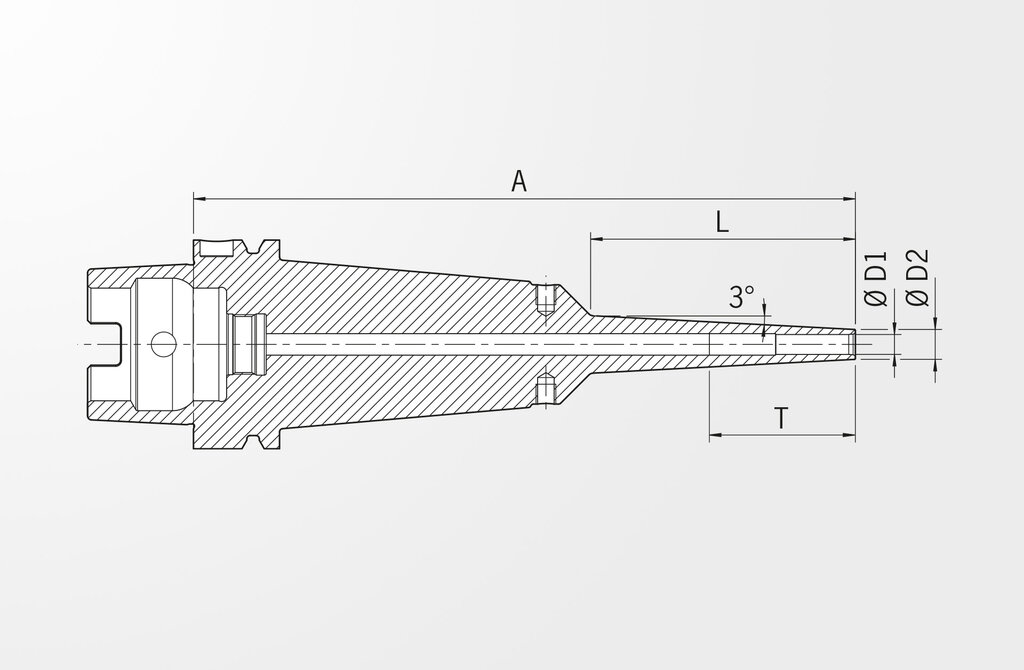

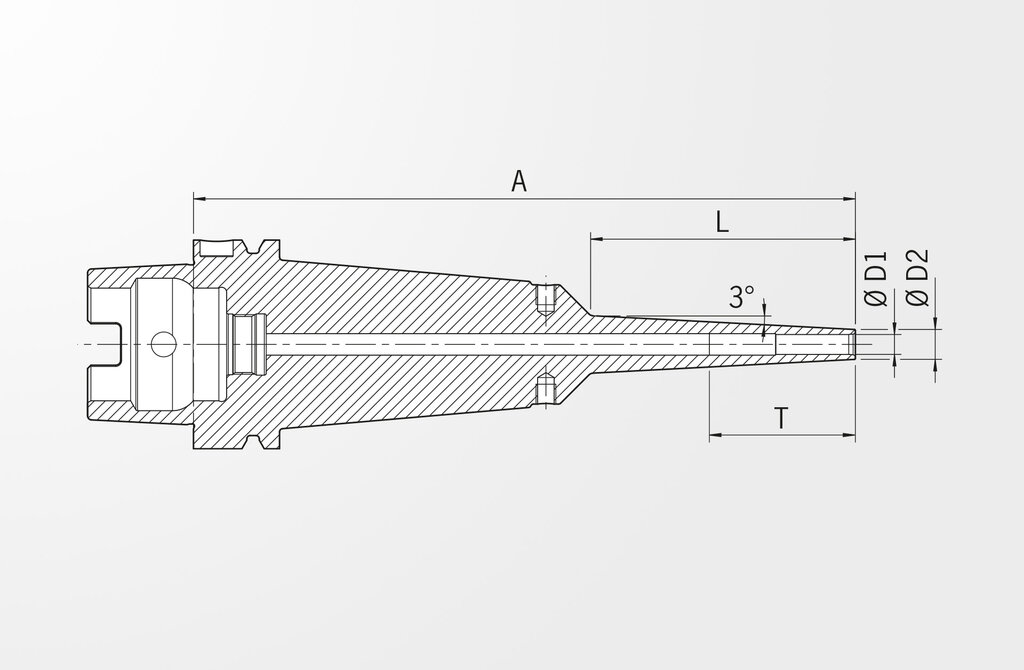

- Extra slim design (1.5 mm wall thickness)

- 3° slope at the top

- With threaded holes in order to balance with balancing screws

- For solid carbide tools with shank tolerance h6

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 0.236 inch |

| Length A | A | 5.118 inch |

| A-length version | AL130 | |

| Diameter 2 | D2 | 0.354 inch |

| Length | L | 1.969 inch |

| Interface | HSK-A63 | |

| Mass (weight) | D7 | 2.617 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | A1 | 0.523 inch |

| Body diameter 2 | A2 | 1.417 inch |

| Body diameter 3 | A22 | 1.496 inch |

| Body diameter 4 | A23 | 2.008 inch |

| Flange diameter | A4 | 2.48 inch |

| Interference diameter | A6 | 0.354 inch |

| Length body diameter 1 | B1 | 1.969 inch |

| Length body diameter 2 | B2 | 0.758 inch |

| Length body diameter 3 | B22 | 0.023 inch |

| Protruding length | B3 | 5.118 inch |

| Overall length | B4 | 6.378 inch |

| Taper angle | B51 | 3 ° |

| Taper angle 2 | B611 | 45 ° |

| Taper angle 3 | B621 | 60 ° |

| Taper angle 4 | B631 | 11 ° |

| Functional length | B71 | 3.701 inch |

| item style code | BLD | 504145 |

| Connection code type machine side | C11 | HSK |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 1 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0630 |

| Connection code type workpiece side | C51 | ZYL |

| Connection code form type workpiece side | C52 | 01 |

| Connection code unit base workpiece side | C54 | 1 |

| Connection code style workpiece side | C55 | 5 |

| Connection size code workpiece side | C6 | 0060 |

| Connection diameter min | C71 | 6 |

| Clamping length max. / nominal length | C81 | 1.417 inch |

| Balancing device | D51 | 1 |

| Hand | E1 | N |

| coolant entry style code | H21 | 1 |

| coolant exit style code | H22 | 1 |

| Company identification | J3 | HAI |

| interface code to workpiece side | J4 | ZYL00600115 |

| interface code to machine side | J6 | HSK06300115 |

| Weight | WT | 2.617 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | BD1 | 0.523 inch |

| Flange diameter | DF | 2.48 inch |

| Interference diameter | DCINTF | 0.354 inch |

| Length body diameter 1 | LBD1 | 1.969 inch |

| Protruding length | LPR | 5.118 inch |

| Overall length | OAL | 6.378 inch |

| Taper angle | TA | 3 ° |

| Functional length | LF | 3.701 inch |

| Connection code type machine side | CCTMS | HSK |

| Connection code unit base workpiece side | CCUWS | 1 |

| Connection code style workpiece side | CCSWS | 5 |

| Connection size code workpiece side | CZCWS | 0060 |

| Connection diameter min | DCONN | 6 |

| Clamping length max. / nominal length | LSCX | 1.417 inch |

| Hand | HAND | N |

| coolant entry style code | CNSC | 1 |

| coolant exit style code | CXSC | 1 |

| Company identification | COMPC | HAI |

Shrink fit chuck suitable to all inductive shrink fit units.

Power Mini Shrink Chuck is perfect for 5-axis-machining in the die & mould and in the medical industry. Very slim at the top like the HAIMER Mini Shrink Chucks, Power Mini Shrink is reinforced at the base. Thereby efficient milling is possible with an angled tool even at long protruding lengths.

- Extra slim design (1.5 mm wall thickness)

- 3° slope at the top

- With threaded holes in order to balance with balancing screws

- For solid carbide tools with shank tolerance h6

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 0.236 inch |

| Length A | A | 5.118 inch |

| A-length version | AL130 | |

| Diameter 2 | D2 | 0.354 inch |

| Length | L | 1.969 inch |

| Interface | HSK-A63 | |

| Mass (weight) | D7 | 2.617 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | A1 | 0.523 inch |

| Body diameter 2 | A2 | 1.417 inch |

| Body diameter 3 | A22 | 1.496 inch |

| Body diameter 4 | A23 | 2.008 inch |

| Flange diameter | A4 | 2.48 inch |

| Interference diameter | A6 | 0.354 inch |

| Length body diameter 1 | B1 | 1.969 inch |

| Length body diameter 2 | B2 | 0.758 inch |

| Length body diameter 3 | B22 | 0.023 inch |

| Protruding length | B3 | 5.118 inch |

| Overall length | B4 | 6.378 inch |

| Taper angle | B51 | 3 ° |

| Taper angle 2 | B611 | 45 ° |

| Taper angle 3 | B621 | 60 ° |

| Taper angle 4 | B631 | 11 ° |

| Functional length | B71 | 3.701 inch |

| item style code | BLD | 504145 |

| Connection code type machine side | C11 | HSK |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 1 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0630 |

| Connection code type workpiece side | C51 | ZYL |

| Connection code form type workpiece side | C52 | 01 |

| Connection code unit base workpiece side | C54 | 1 |

| Connection code style workpiece side | C55 | 5 |

| Connection size code workpiece side | C6 | 0060 |

| Connection diameter min | C71 | 6 |

| Clamping length max. / nominal length | C81 | 1.417 inch |

| Balancing device | D51 | 1 |

| Hand | E1 | N |

| coolant entry style code | H21 | 1 |

| coolant exit style code | H22 | 1 |

| Company identification | J3 | HAI |

| interface code to workpiece side | J4 | ZYL00600115 |

| interface code to machine side | J6 | HSK06300115 |

| Weight | WT | 2.617 lbs |

| Standard number of properties layout | NSM | DIN4000-89 |

| Body diameter 1 | BD1 | 0.523 inch |

| Flange diameter | DF | 2.48 inch |

| Interference diameter | DCINTF | 0.354 inch |

| Length body diameter 1 | LBD1 | 1.969 inch |

| Protruding length | LPR | 5.118 inch |

| Overall length | OAL | 6.378 inch |

| Taper angle | TA | 3 ° |

| Functional length | LF | 3.701 inch |

| Connection code type machine side | CCTMS | HSK |

| Connection code unit base workpiece side | CCUWS | 1 |

| Connection code style workpiece side | CCSWS | 5 |

| Connection size code workpiece side | CZCWS | 0060 |

| Connection diameter min | DCONN | 6 |

| Clamping length max. / nominal length | LSCX | 1.417 inch |

| Hand | HAND | N |

| coolant entry style code | CNSC | 1 |

| coolant exit style code | CXSC | 1 |

| Company identification | COMPC | HAI |

| Order No. | A-length version | Clamping diameter | Interface | Length A | Downloads | metric/ inch |

|---|---|---|---|---|---|---|

| A63.172.03.8 | oversize (160 mm) | 0.118 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.04.8 | oversize (160 mm) | 0.157 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.05.8 | oversize (160 mm) | 0.197 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.06.8 | oversize (160 mm) | 0.236 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.08.8 | oversize (160 mm) | 0.315 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.1/2Z.8 | oversize (160 mm) | 1/2 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.1/4Z.8 | oversize (160 mm) | 1/4 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.1/8Z.8 | oversize (160 mm) | 1/8 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.10.8 | oversize (160 mm) | 0.394 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.12.8 | oversize (160 mm) | 0.472 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.3/16Z.8 | oversize (160 mm) | 3/16 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.3/8Z.8 | oversize (160 mm) | 3/8 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.172.5/16Z.8 | oversize (160 mm) | 5/16 inch | HSK-A63 | 6.299 inch |

Download after registration

|

|

| A63.174.03.8 | AL130 | 0.118 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.04.8 | AL130 | 0.157 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.05.8 | AL130 | 0.197 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.06.8 | AL130 | 0.236 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.08.8 | AL130 | 0.315 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.1/2Z.8 | AL130 | 1/2 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.1/4Z.8 | AL130 | 1/4 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.1/8Z.8 | AL130 | 1/8 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.10.8 | AL130 | 0.394 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.12.8 | AL130 | 0.472 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.3/16Z.8 | AL130 | 3/16 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.3/8Z.8 | AL130 | 3/8 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.174.5/16Z.8 | AL130 | 5/16 inch | HSK-A63 | 5.118 inch |

Download after registration

|

|

| A63.176.03.8 | ZG200 | 0.118 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.04.8 | ZG200 | 0.157 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.05.8 | ZG200 | 0.197 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.06.8 | ZG200 | 0.236 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.08.8 | ZG200 | 0.315 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.1/2Z.8 | ZG200 | 1/2 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.1/4Z.8 | ZG200 | 1/4 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.1/8Z.8 | ZG200 | 1/8 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.10.8 | ZG200 | 0.394 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.12.8 | ZG200 | 0.472 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.3/16Z.8 | ZG200 | 3/16 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.3/8Z.8 | ZG200 | 3/8 inch | HSK-A63 | 7.874 inch |

Download after registration

|

|

| A63.176.5/16Z.8 | ZG200 | 5/16 inch | HSK-A63 | 7.874 inch |

Download after registration

|

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001