HAIMER MILL - F2004MN Sharp Cutting Edge

Solid carbide end mill

Characteristics

Helix angle 37/39°

Helix angle 37/39°

Sharp cutting edge

Sharp cutting edge

Teeth 4

Teeth 4

Applications

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Ramping

Ramping

Slotting

Slotting

Side milling

Side milling

Drilling

Drilling

Areas of application-material

Steel

Steel

Stainless steel

Stainless steel

Cast iron

Cast iron

High temperature alloys and titanium alloys

High temperature alloys and titanium alloys

NF metals

NF metals

Hard materials

Hard materials

HAIMER MILL - F2004MN Sharp Cutting Edge

Solid carbide end mill

Quality pass

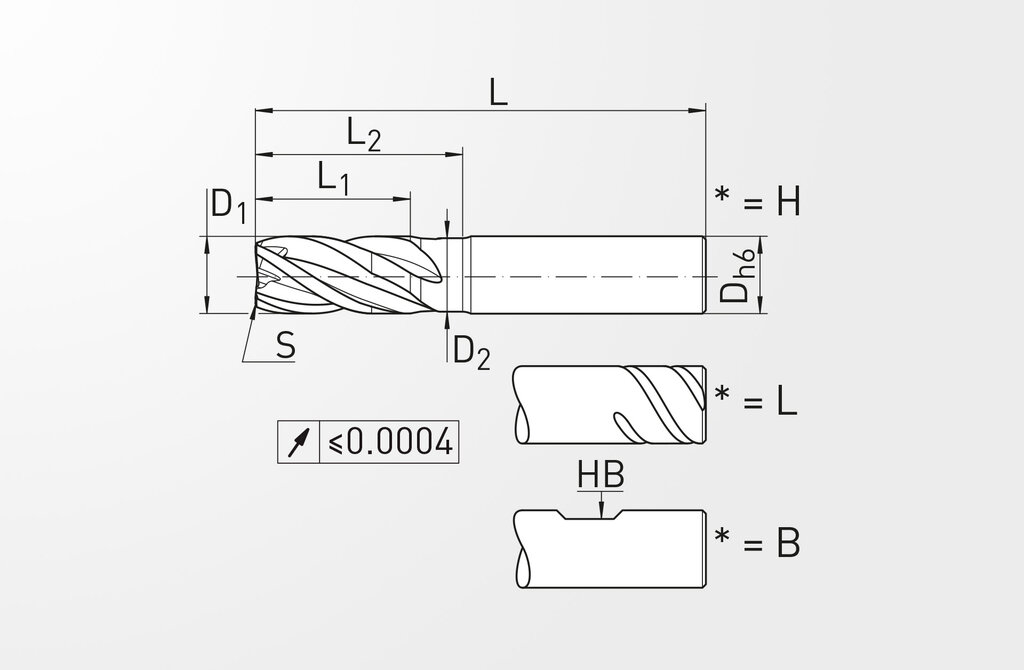

Shank tolerance h6

Runout < 0.0004" (10 µm)

Universal solid carbide end mill for a broad range of applications

- Shank tolerance: h6

- Neck for higher cutting depth

- Center cutting

- Unequal cutting edge

- Runout < 0.0004" (10 µm)

- For almost all materials

- For roughing and finishing

- For ramping, drilling and slotting

HAIMER MILL - F2004MN Sharp Cutting Edge

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Diameter | D | 1/2 inch |

| D1 Tolerance | f9 | |

| Corner design | S | |

| Length | L | 3.5 inch |

| Shank version | Weldon shank | |

| Helix angle | 37/39 ° | |

| HAIMER Material | D | |

| HAIMER Coating | A | |

| Mass (weight) | D7 | 0.309 lbs |

| Weight | WT | 0.309 lbs |

Characteristics

Helix angle 37/39°

Helix angle 37/39°

Helix angle 37/39°

Helix angle 37/39°

Sharp cutting edge

Sharp cutting edge

Sharp cutting edge

Sharp cutting edge

Teeth 4

Teeth 4

Teeth 4

Teeth 4

Applications

- For almost all materials

- For roughing and finishing

- For ramping, drilling and slotting

AREAS OF APPLICATION - MATERIAL

MAIN AREA OF APPLICATION

Steel

P

All types of steel and cast steel, with the exception of steel with an austenitic structure

Stainless steel

M

Stainless austenitic steel and austenitic-ferritic steel and cast steel

FURTHER AREAS OF APPLICATION

Cast iron

K

Grey cast iron, cast iron with spheroidal graphite, malleable cast iron, cast iron with vermicular graphite

High temperature alloys and titanium alloys

S

Heat resisting special alloys based on iron, nickel and cobalt, titanium and titanium alloys

NF metals

N

Aluminium and other non-ferrous metals, non ferrous materials

Hard materials

H

Hardened steel, hardened cast iron materials, chilled cast iron

Operations

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Ramping

Ramping

Slotting

Slotting

Side milling

Side milling

Drilling

Drilling

Cooling

Emulsion

Emulsion

Cold air

Cold air

Dry machining

Dry machining

Minimal lubrication

Minimal lubrication

Cutting Data

HAIMER MILL - F2004MN Sharp Cutting Edge

Description

HAIMER MILL - F2004MN Sharp Cutting Edge

Solid carbide end mill

Quality pass

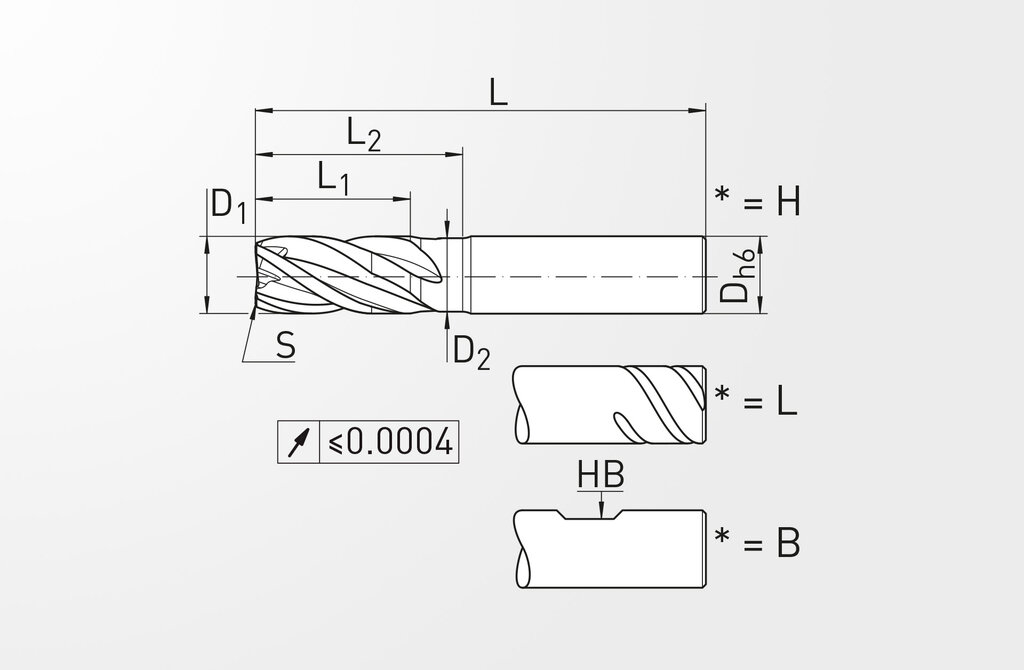

Shank tolerance h6

Runout < 0.0004" (10 µm)

Universal solid carbide end mill for a broad range of applications

- Shank tolerance: h6

- Neck for higher cutting depth

- Center cutting

- Unequal cutting edge

- Runout < 0.0004" (10 µm)

- For almost all materials

- For roughing and finishing

- For ramping, drilling and slotting

Technical specifications

HAIMER MILL - F2004MN Sharp Cutting Edge

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Diameter | D | 1/2 inch |

| D1 Tolerance | f9 | |

| Corner design | S | |

| Length | L | 3.5 inch |

| Shank version | Weldon shank | |

| Helix angle | 37/39 ° | |

| HAIMER Material | D | |

| HAIMER Coating | A | |

| Mass (weight) | D7 | 0.309 lbs |

| Weight | WT | 0.309 lbs |

Characteristics

Helix angle 37/39°

Helix angle 37/39°

Helix angle 37/39°

Helix angle 37/39°

Sharp cutting edge

Sharp cutting edge

Sharp cutting edge

Sharp cutting edge

Teeth 4

Teeth 4

Teeth 4

Teeth 4

applications

Applications

- For almost all materials

- For roughing and finishing

- For ramping, drilling and slotting

AREAS OF APPLICATION - MATERIAL

MAIN AREA OF APPLICATION

Steel

P

All types of steel and cast steel, with the exception of steel with an austenitic structure

Stainless steel

M

Stainless austenitic steel and austenitic-ferritic steel and cast steel

FURTHER AREAS OF APPLICATION

Cast iron

K

Grey cast iron, cast iron with spheroidal graphite, malleable cast iron, cast iron with vermicular graphite

High temperature alloys and titanium alloys

S

Heat resisting special alloys based on iron, nickel and cobalt, titanium and titanium alloys

NF metals

N

Aluminium and other non-ferrous metals, non ferrous materials

Hard materials

H

Hardened steel, hardened cast iron materials, chilled cast iron

Operations

Feed direction (Side milling, Ramping, Drilling)

Feed direction (Side milling, Ramping, Drilling)

Ramping

Ramping

Slotting

Slotting

Side milling

Side milling

Drilling

Drilling

Cooling

Emulsion

Emulsion

Cold air

Cold air

Dry machining

Dry machining

Minimal lubrication

Minimal lubrication

Cutting Data

Cutting Data

HAIMER MILL - F2004MN Sharp Cutting Edge

All product variants

With the help of our filter you can refine your search by selecting attributes.

Filter

| Order No. | Corner design | HAIMER Coating | Shank version | Downloads | metric/ inch |

|---|---|---|---|---|---|

| F2004MNB1/2ZSDA | S | A | Weldon shank |

|

|

| F2004MNB1/4ZSDA | S | A | Weldon shank |

|

|

| F2004MNB1/8ZSDA | S | A | Weldon shank |

|

|

| F2004MNB3/16ZSDA | S | A | Weldon shank |

|

|

| F2004MNB3/32ZSDA | S | A | Weldon shank |

|

|

| F2004MNB3/4ZSDA | S | A | Weldon shank |

|

|

| F2004MNB3/8ZSDA | S | A | Weldon shank |

|

|

| F2004MNB5/16ZSDA | S | A | Weldon shank |

|

|

| F2004MNB5/8ZSDA | S | A | Weldon shank |

|

|

| F2004MNH1/2ZSDA | S | A | Straight shank |

|

|

| F2004MNH1/4ZSDA | S | A | Straight shank |

|

|

| F2004MNH1/8ZSDA | S | A | Straight shank |

|

|

| F2004MNH3/16ZSDA | S | A | Straight shank |

|

|

| F2004MNH3/32ZSDA | S | A | Straight shank |

|

|

| F2004MNH3/4ZSDA | S | A | Straight shank |

|

|

| F2004MNH3/8ZSDA | S | A | Straight shank |

|

|

| F2004MNH5/16ZSDA | S | A | Straight shank |

|

|

| F2004MNH5/8ZSDA | S | A | Straight shank |

|

|

| F2004MNL1/2ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL1/4ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL1/8ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL3/16ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL3/32ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL3/4ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL3/8ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL5/16ZSDA | S | A | Safe-λock® |

|

|

| F2004MNL5/8ZSDA | S | A | Safe-λock® |

|

Haimer Care

The quality at Haimer is not only

by the product, but also by the

accompanying services.

Scope of service

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001