Balancing machine to balance tool holders on 1 plane.

The balancing device Tool Dynamic TD 1002 is your start into the modular balancing system of the Tool Dynamic series. Designed as a table and complementary machine, it is the ideal solution for mould makers, small batch lots, single applications and standard chucks. The Tool Dynamic TD 1002 measures and compensates the unbalance in one plane (static). Therefore it is perfect for balancing short tool holders and tools because of the couple unbalance being very low. The device is operated via the integrated keyboard and screen.

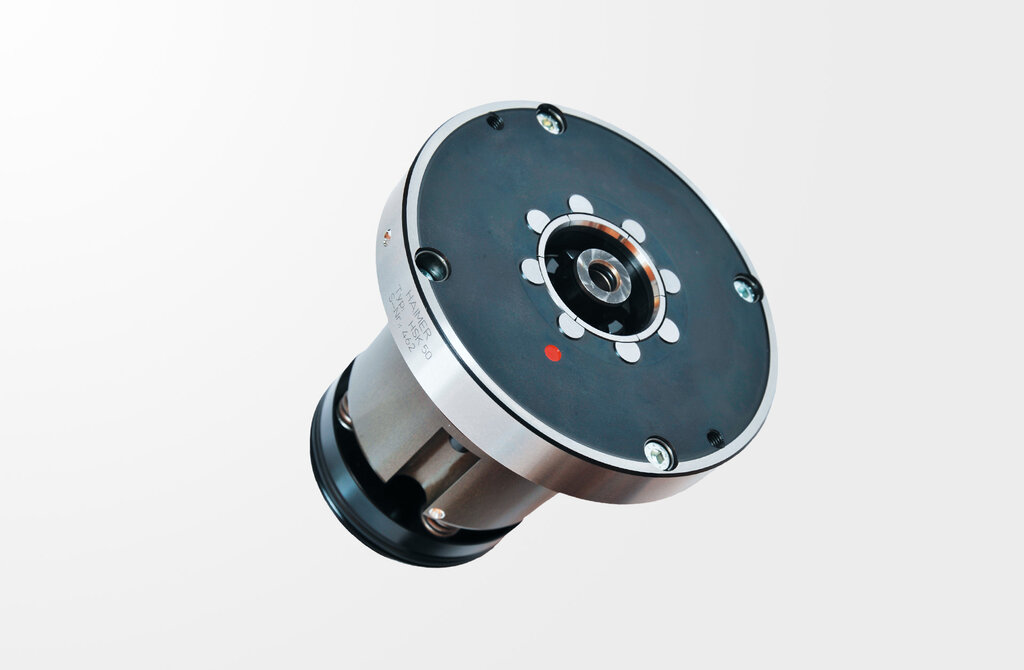

Picture shows balancing device TD 1002 with optional runout measuring device.