Shrink fit chuck suitable to all inductive shrink fit units.

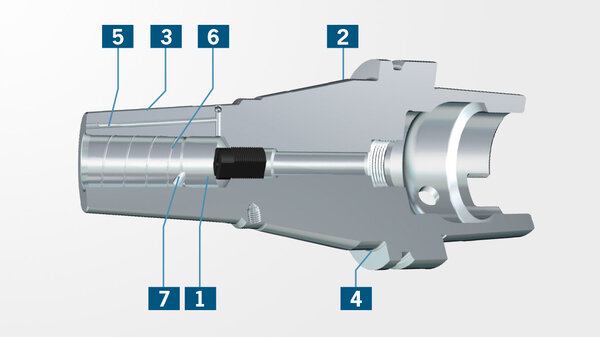

The Power Shrink Chuck is designed for the highest cutting performance in High Speed machining. The optimized design combines high rigidity with vibration dampening, which protects the machine, spindle and tool.

Shrink Fit Chuck Power Shrink Chuck, Similar ASME B5.50 · CAT50 With Face Contact

- Additional support on the flange surface for more rigidity

- Highest cutting performance with higher spindle speeds, higher feeds and larger cutting dephts

- Shorter cycle times, higher machining accurancy

- Quiter running, therefore better surface quality and protection of tools, spindles and machines

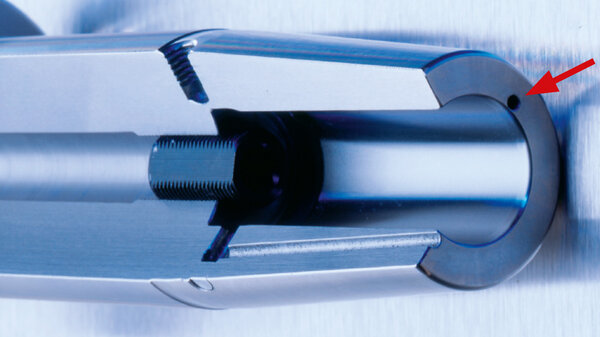

- With threaded holes in order to balance with balancing screws

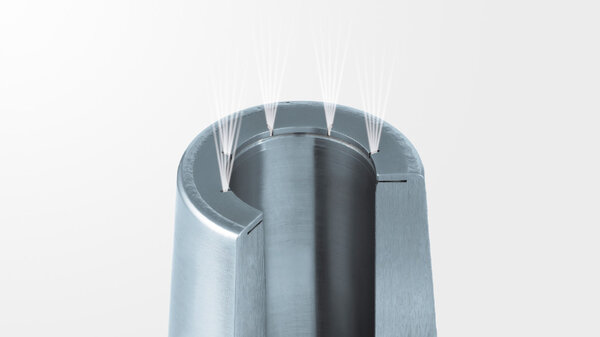

- Cool Jet coolant bores that can be sealed included

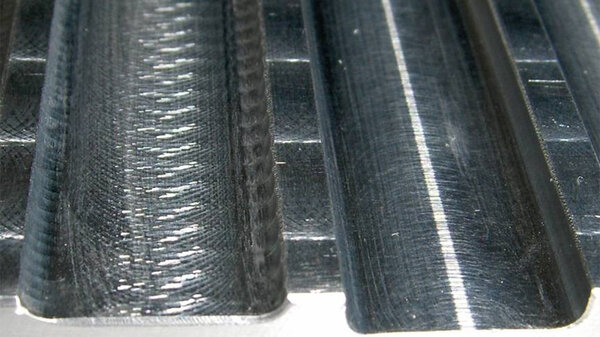

- High rigidity, slim at the tip, dampen vibrations

- Higher clamping forces

- Equally suited to High Speed and Heavy Duty machining

- Universal usage, saves space in tool magazine

- Compatible with Big-Plus spindles

| Descripción | Norma: | Valor: metric/ inch |

|---|---|---|

| Diámetro de sujeción | D1 | 12,7 mm |

| Longitud A | A | 80 mm |

| Versión de longitud A | corto | |

| Diámetro 2 | D2 | 27 mm |

| Diámetro 3 | D3 | 55 mm |

| Longitud | L | 47 mm |

| Interfaz | CAT50 con doble contacto | |

| Actualización | con Cool Jet | |

| Masa (peso) | D7 | 3,271 kg |

| Weight | WT | 3,271 kg |

Shrink fit chuck suitable to all inductive shrink fit units.

The Power Shrink Chuck is designed for the highest cutting performance in High Speed machining. The optimized design combines high rigidity with vibration dampening, which protects the machine, spindle and tool.

- Additional support on the flange surface for more rigidity

- Highest cutting performance with higher spindle speeds, higher feeds and larger cutting dephts

- Shorter cycle times, higher machining accurancy

- Quiter running, therefore better surface quality and protection of tools, spindles and machines

- With threaded holes in order to balance with balancing screws

- Cool Jet coolant bores that can be sealed included

- High rigidity, slim at the tip, dampen vibrations

- Higher clamping forces

- Equally suited to High Speed and Heavy Duty machining

- Universal usage, saves space in tool magazine

- Compatible with Big-Plus spindles

| Descripción | Norma: | Valor: metric/ inch |

|---|---|---|

| Diámetro de sujeción | D1 | 12,7 mm |

| Longitud A | A | 80 mm |

| Versión de longitud A | corto | |

| Diámetro 2 | D2 | 27 mm |

| Diámetro 3 | D3 | 55 mm |

| Longitud | L | 47 mm |

| Interfaz | CAT50 con doble contacto | |

| Actualización | con Cool Jet | |

| Masa (peso) | D7 | 3,271 kg |

| Weight | WT | 3,271 kg |

| Número de pedido | Actualización | Diámetro de sujeción | Interfaz | Longitud A | Versión de longitud A | Downloads | metric/ inch |

|---|---|---|---|---|---|---|---|

| 50P.840.1/2Z.3 | con Cool Jet | 12,7 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.1/2Z.37 | con Safe-Lock y Cool Jet | 12,7 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.1/4Z.3 | con Cool Jet | 6,35 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.1Z.3 | con Cool Jet | 25,4 mm | CAT50 con doble contacto | 100 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.1Z.37 | con Safe-Lock y Cool Jet | 25,4 mm | CAT50 con doble contacto | 100 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.3/4Z.3 | con Cool Jet | 19,05 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.3/4Z.37 | con Safe-Lock y Cool Jet | 19,05 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.3/8Z.3 | con Cool Jet | 9,525 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.5/16Z.3 | con Cool Jet | 7,9375 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.5/8Z.3 | con Cool Jet | 15,875 mm | CAT50 con doble contacto | 80 mm | corto |

Descargar tras registrarse

|

|

| 50P.840.5/8Z.37 | con Safe-Lock y Cool Jet | 15,875 mm | CAT50 con doble contacto | 80 mm | corto |

|

- Detección precoz del desgaste

- Preservación de la condición de objetivo

- Alta disponibilidad de especialistas HAIMER

- Nivel de calidad constante

- Requisito previo para la certificación según la norma ISO 9001