Shrink Fit Chuck Standard Version, DIN 69893-6, HSK-F80 Makino

Shrink Fit Chuck Standard Version, DIN 69893-6, HSK-F80 Makino

Quality pass

Chuck fine balanced G2.5 at 33.000 rpm

All functional surfaces fine machined

More accurate than DIN

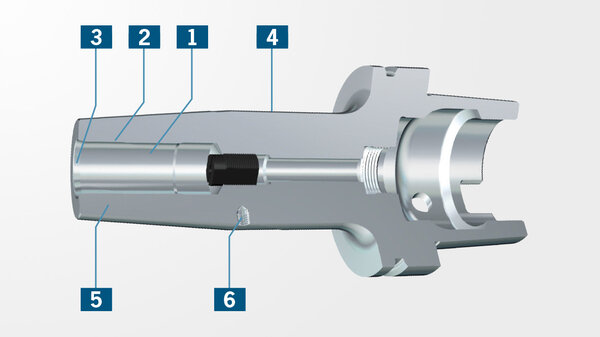

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Holder pre-balanced to G2.5 at 33,000 RPM or U < 1 gmm

- Short gage length per machine builders recommendation

- Dampen vibrations

- High clamping force

- Equally suited to high-speed manufacturing and heavy milling

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times

- Higher machining accuracy

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Heat resistant hot-working steel

- Hardened 54-2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- All standard as a balanceable for fine tune balancing capability

Scope of Delivery

- With backup screw

HAIMER TIP

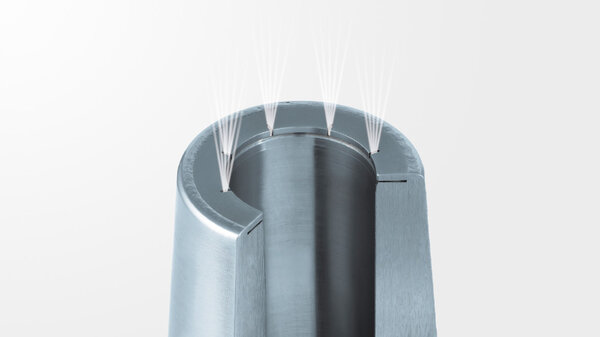

For a constant and acurate cooling of te cutting tool we recommend the optional cooling system Cool Jet.

Shrink Fit Chuck Standard Version, DIN 69893-6, HSK-F80 Makino

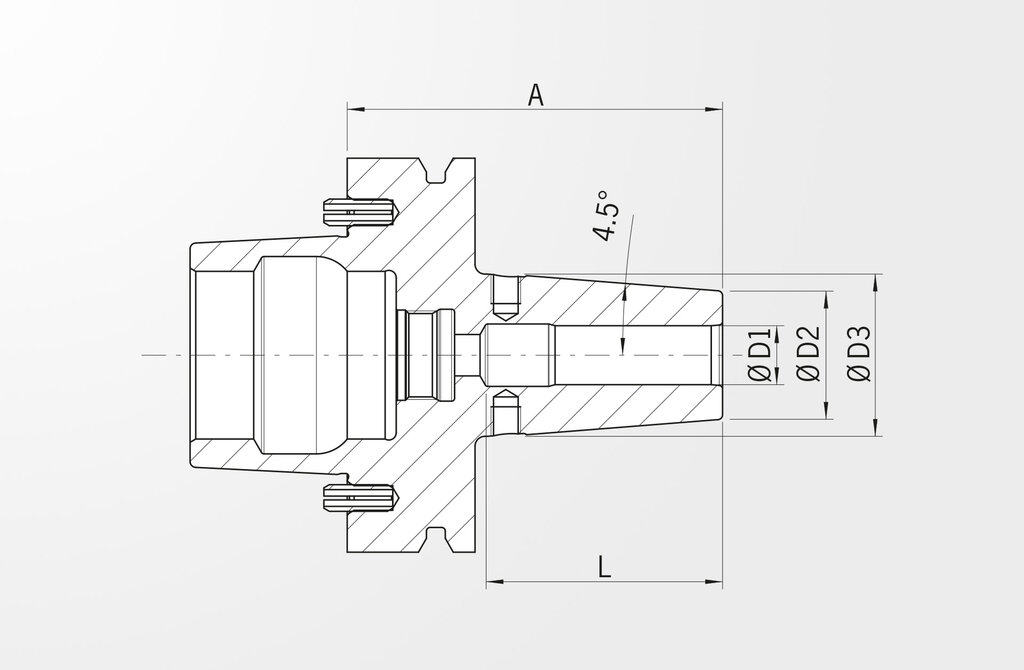

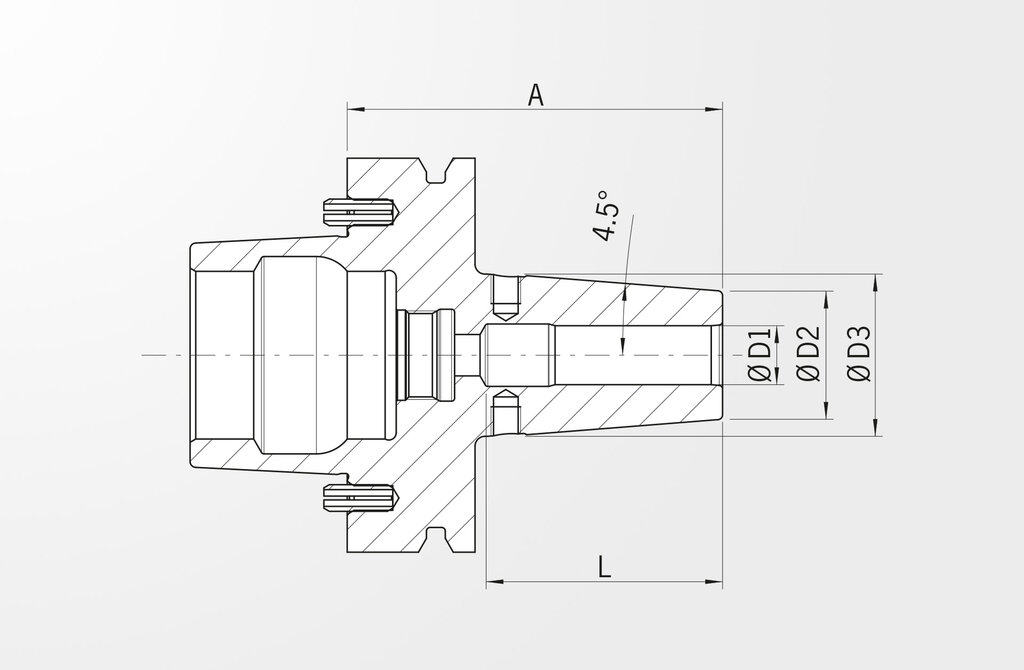

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 6 mm |

| Length A | A | 76,2 mm |

| A-length version | ultra short | |

| Diameter 2 | D2 | 21 mm |

| Diameter 3 | D3 | 27 mm |

| Length | L | 36 mm |

| Interface | HSK-F80M | |

| Mass (weight) | D7 | 1,230 kg |

| Balance grade | D5 | G2,5/25000 |

| Rotation speed, max | D6 | 25000 |

| Company identification | J3 | HAI |

| Weight | WT | 1,230 kg |

| Company identification | COMPC | HAI |

Downloads

Register to get access to free downloads of CAD data (DXF and STP) on our product websites.

Description

Shrink Fit Chuck Standard Version, DIN 69893-6, HSK-F80 Makino

Quality pass

Chuck fine balanced G2.5 at 33.000 rpm

All functional surfaces fine machined

More accurate than DIN

For heavy machining applications it is now possible to replace the Weldon tool holders finally. Heavy Duty Chuck is the shrink fit chuck for extreme cases. The contour is optimized for highest rigidity and clamping force.

- Holder pre-balanced to G2.5 at 33,000 RPM or U < 1 gmm

- Short gage length per machine builders recommendation

- Dampen vibrations

- High clamping force

- Equally suited to high-speed manufacturing and heavy milling

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times

- Higher machining accuracy

- Quieter running, therefore better surface quality and protection of tools, spindles and machines

- Heat resistant hot-working steel

- Hardened 54-2 HRC

- For HSS and solid carbide tools

- Shank tolerance h6

- All standard as a balanceable for fine tune balancing capability

Scope of Delivery

- With backup screw

HAIMER TIP

For a constant and acurate cooling of te cutting tool we recommend the optional cooling system Cool Jet.

Technical specifications

Shrink Fit Chuck Standard Version, DIN 69893-6, HSK-F80 Makino

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Clamping diameter | D1 | 6 mm |

| Length A | A | 76,2 mm |

| A-length version | ultra short | |

| Diameter 2 | D2 | 21 mm |

| Diameter 3 | D3 | 27 mm |

| Length | L | 36 mm |

| Interface | HSK-F80M | |

| Mass (weight) | D7 | 1,230 kg |

| Balance grade | D5 | G2,5/25000 |

| Rotation speed, max | D6 | 25000 |

| Company identification | J3 | HAI |

| Weight | WT | 1,230 kg |

| Company identification | COMPC | HAI |

Downloads

Downloads

Register to get access to free downloads of CAD data (DXF and STP) on our product websites.

All product variants

With the help of our filter you can refine your search by selecting attributes.

Filter

| Order No. | A-length version | Clamping diameter | Interface | Length A | Downloads | metric/ inch |

|---|---|---|---|---|---|---|

| F80M.145.06 | ultra short | 6 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.08 | ultra short | 8 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.10 | ultra short | 10 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.12 | ultra short | 12 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.14 | ultra short | 14 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.16 | ultra short | 16 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.20 | ultra short | 20 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.20.5 | ultrakurz - ultrakurz | 20 mm | HSK-F80M | 70 mm |

Download after registration

|

|

| F80M.145.25 | ultra short | 25 mm | HSK-F80M | 76,2 mm |

Download after registration

|

|

| F80M.145.25.5 | ultrakurz - ultrakurz | 25 mm | HSK-F80M | 70 mm |

Download after registration

|

Haimer Care

The quality at Haimer is not only

by the product, but also by the

accompanying services.

Scope of service

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001