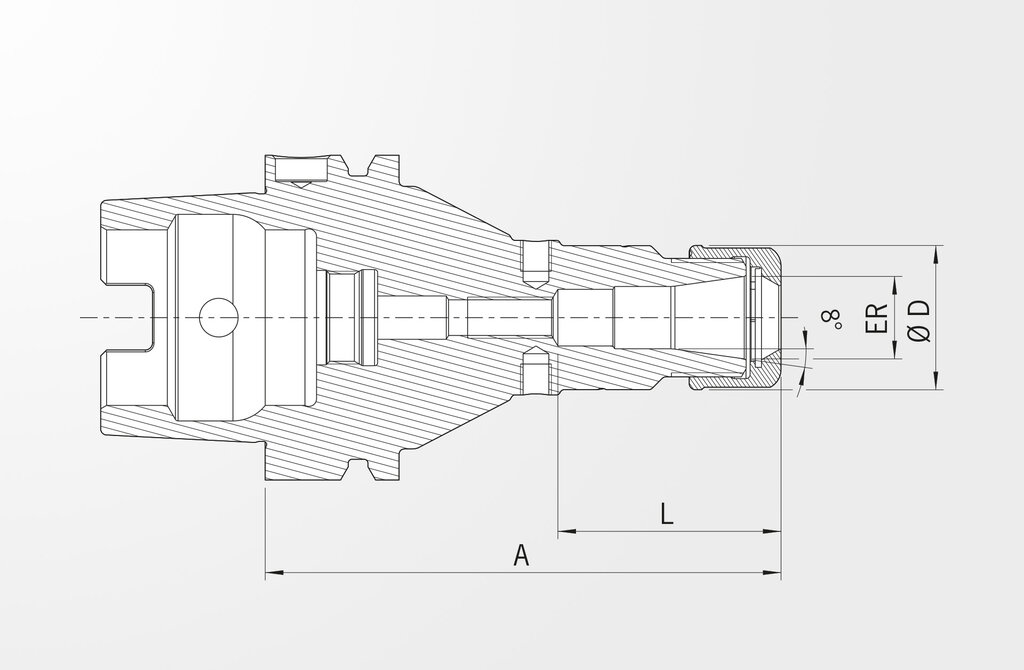

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The High Precision Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with an improved construction and a specially coated smooth locknut combines high rigidity with vibration damping and noise reduction. This protects the machine, spindle, and tool. The universal High Precision Collet Chuck is a unique high-performance tool holder that can also be used with standard collets.

High Precision Collet Chuck, DIN 69893-1, HSK-A63

- With a specially coated smooth locknut, balanced at < 1 gmm

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also suitable for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary.)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- With threaded holes in order to balance with balancing screws

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Size | ER16 | |

| Clamping range | 2,0-10,0 | |

| Length A | A | 100 mm |

| A-length version | short | |

| Length | L | 43 mm |

| Interface | HSK-A63 | |

| Mass (weight) | D7 | 1,191 kg |

| Flange diameter | A4 | 63 mm |

| Connection code type machine side | C11 | HSK |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 1 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0630 |

| Connection code type workpiece side | C51 | SZD |

| Connection code form type workpiece side | C52 | 02 |

| Connection code unit base workpiece side | C54 | 9 |

| Connection code style workpiece side | C55 | 5 |

| Connection size code workpiece side | C6 | 0160 |

| Balance grade | D5 | G2,5/30000 |

| Hand | E1 | N |

| coolant exit style code | H22 | 1 |

| Company identification | J3 | HAI |

| interface code to workpiece side | J4 | SZD01600295 |

| interface code to machine side | J6 | HSK06300115 |

| Weight | WT | 1,191 kg |

| Flange diameter | DF | 63 mm |

| Connection code type machine side | CCTMS | HSK |

| Connection code unit base workpiece side | CCUWS | 9 |

| Connection code style workpiece side | CCSWS | 5 |

| Connection size code workpiece side | CZCWS | 0160 |

| Hand | HAND | N |

| coolant exit style code | CXSC | 1 |

| Company identification | COMPC | HAI |

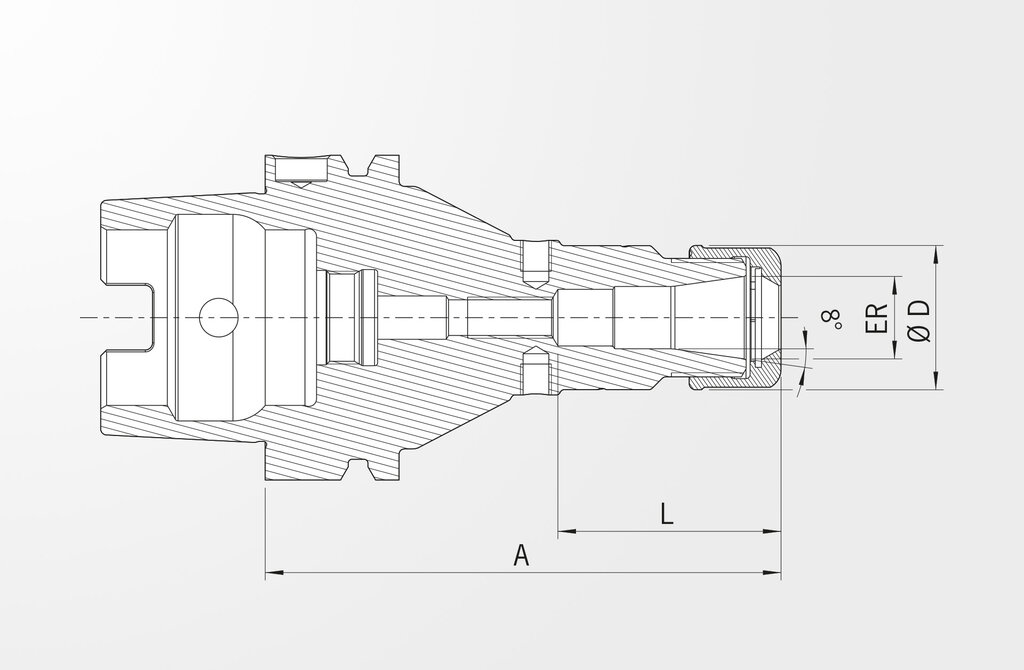

For clamping tools with cylindrical shank in HAIMER Power Collets and ER collets according to ISO 15488.

The High Precision Collet Chuck is the collet chuck for the highest machining capacity in high-speed manufacturing. The optimized design with an improved construction and a specially coated smooth locknut combines high rigidity with vibration damping and noise reduction. This protects the machine, spindle, and tool. The universal High Precision Collet Chuck is a unique high-performance tool holder that can also be used with standard collets.

- With a specially coated smooth locknut, balanced at < 1 gmm

- High runout accuracy: 0.003 mm at 3 × D with HAIMER Power Collets

- Also suitable for standard collets ER according to ISO 15488 (Please note when use with standard ER collets the gage length A will vary.)

- High rigidity

- Smoother running thanks to vibration absorbing geometry, therefore better surface quality and protection of tools, spindles and machines

- Increased machining capacity due to higher spindle speeds, higher feed rates and larger cutting depths

- Shorter processing times, higher machining accuracy, high clamping force

- Equally suited to high-speed manufacturing and heavy milling

- With threaded holes in order to balance with balancing screws

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Size | ER16 | |

| Clamping range | 2,0-10,0 | |

| Length A | A | 100 mm |

| A-length version | short | |

| Length | L | 43 mm |

| Interface | HSK-A63 | |

| Mass (weight) | D7 | 1,191 kg |

| Flange diameter | A4 | 63 mm |

| Connection code type machine side | C11 | HSK |

| Connection code form type machine side | C12 | 01 |

| Connection code unit base machine side | C14 | 1 |

| Connection code style machine side | C15 | 5 |

| Connection size code machine side | C2 | 0630 |

| Connection code type workpiece side | C51 | SZD |

| Connection code form type workpiece side | C52 | 02 |

| Connection code unit base workpiece side | C54 | 9 |

| Connection code style workpiece side | C55 | 5 |

| Connection size code workpiece side | C6 | 0160 |

| Balance grade | D5 | G2,5/30000 |

| Hand | E1 | N |

| coolant exit style code | H22 | 1 |

| Company identification | J3 | HAI |

| interface code to workpiece side | J4 | SZD01600295 |

| interface code to machine side | J6 | HSK06300115 |

| Weight | WT | 1,191 kg |

| Flange diameter | DF | 63 mm |

| Connection code type machine side | CCTMS | HSK |

| Connection code unit base workpiece side | CCUWS | 9 |

| Connection code style workpiece side | CCSWS | 5 |

| Connection size code workpiece side | CZCWS | 0160 |

| Hand | HAND | N |

| coolant exit style code | CXSC | 1 |

| Company identification | COMPC | HAI |

| Order No. | A-length version | Clamping range | Interface | Length A | Size | Downloads | metric/ inch |

|---|---|---|---|---|---|---|---|

| A63.020.16.3.HP | short | 2,0-10,0 | HSK-A63 | 100 mm | ER16 |

Download after registration

|

|

| A63.020.25.3.HP | short | 2,0-16,0 | HSK-A63 | 100 mm | ER25 |

Download after registration

|

|

| A63.020.32.3.HP | short | 2,0-20,0 | HSK-A63 | 100 mm | ER32 |

Download after registration

|

|

| A63.022.16.3.HP | oversize (160 mm) | 2,0-10,0 | HSK-A63 | 160 mm | ER16 |

Download after registration

|

|

| A63.022.25.3.HP | oversize (160 mm) | 2,0-16,0 | HSK-A63 | 160 mm | ER25 |

Download after registration

|

|

| A63.022.32.3.HP | oversize (160 mm) | 2,0-20,0 | HSK-A63 | 160 mm | ER32 |

Download after registration

|

|

| A63.025.16.3.HP | ultra short | 2,0-10,0 | HSK-A63 | 75 mm | ER16 |

Download after registration

|

|

| A63.025.25.3.HP | ultra short | 2,0-16,0 | HSK-A63 | 75 mm | ER25 |

|

|

| A63.025.32.3.HP | ultra short | 2,0-20,0 | HSK-A63 | 75 mm | ER32 |

Download after registration

|

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001