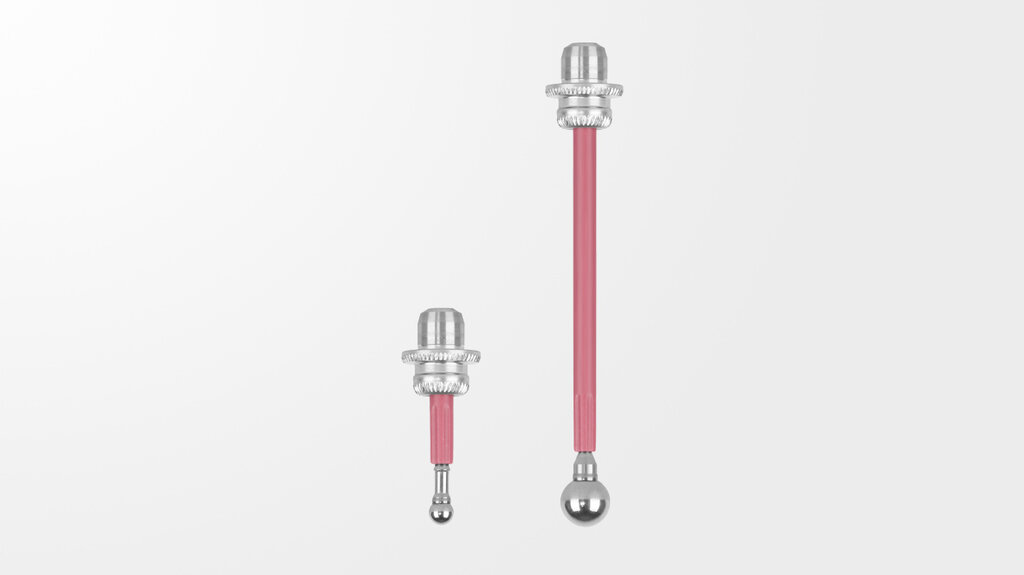

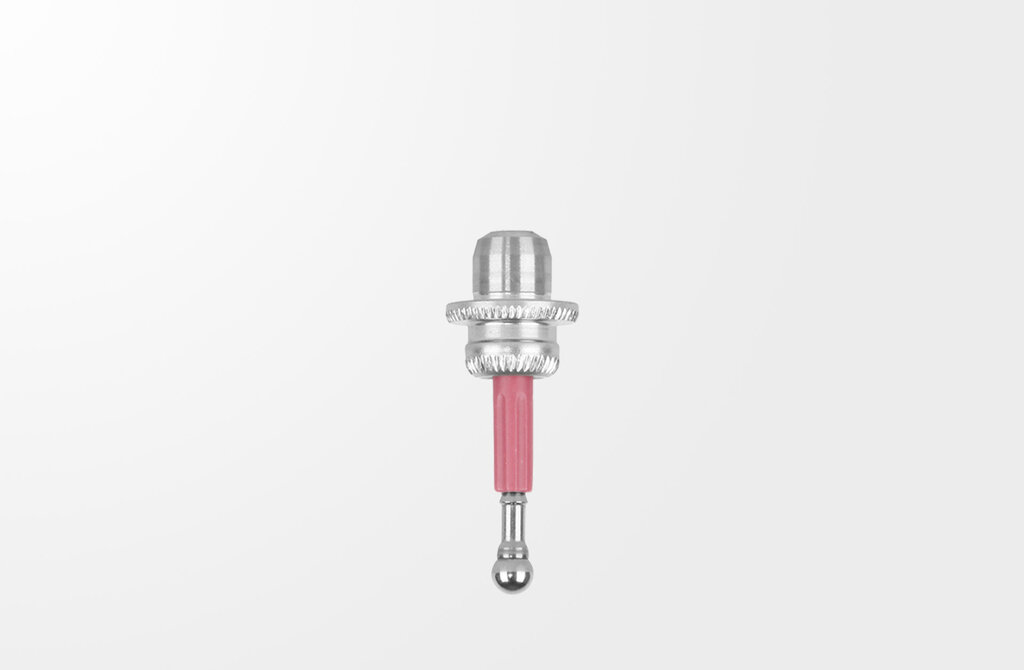

The Zero Master is the smallest 3D-Sensor worldwide. Usage, function and accuracy are equal to the Universal 3D-Sensor. The size of the Zero Master is adapted to small machines.

The diameter of the clamping shank is 10 mm. Thus it can be also used on machines with ISO 30 or small HSK spindles. The housing is shortened and does not protrude far out of the spindle so even big work pieces can be measured. The Zero Master can be read with a small analog dial gauge.

The Sensor is waterproof according to IP 67.

Please take note: The given measuring precision of 0.01 mm only applies if the original HAIMER probe tips are used.

Included in delivery: Zero Master with clamping shank Ø 10 mm, short probe tip Ø 4 mm

3D-Sensor Zero Master

Zero Master with clamping shank Ø 10 mm, short probe tip Ø 4 mm

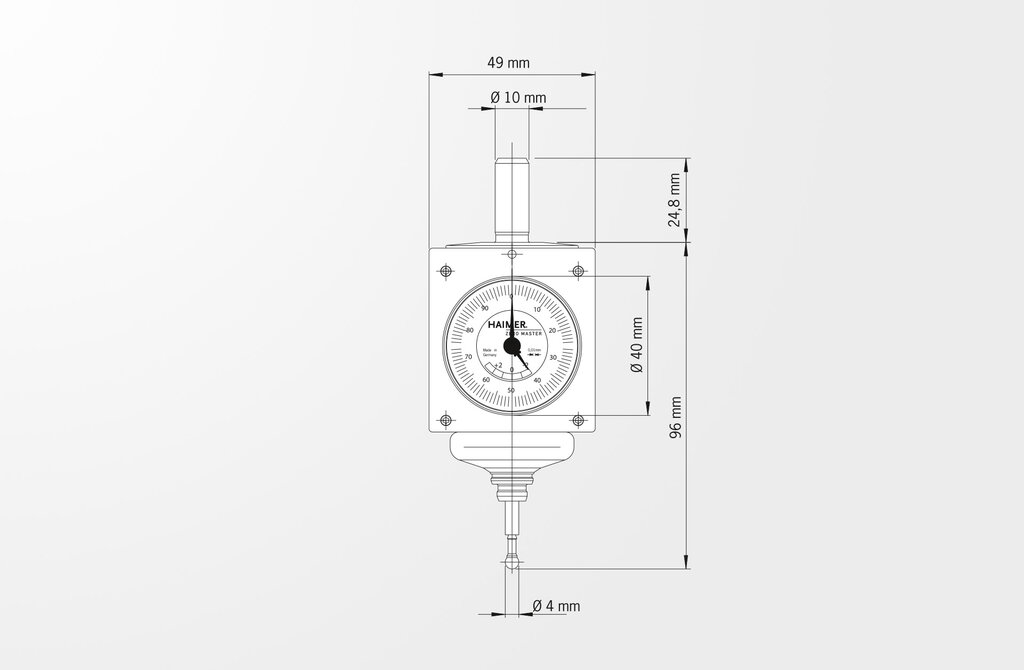

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Version | Metric | |

| Length 1 | L1 | 96 mm |

| Length 2 | L2 | 24,8 mm |

| Diameter 1 | D1 | 10 mm |

| Diameter 2 | D2 | 4 mm |

| Width | B | 49 mm |

| Smallest unit of measure | 0,01 mm |

The Zero Master is the smallest 3D-Sensor worldwide. Usage, function and accuracy are equal to the Universal 3D-Sensor. The size of the Zero Master is adapted to small machines.

The diameter of the clamping shank is 10 mm. Thus it can be also used on machines with ISO 30 or small HSK spindles. The housing is shortened and does not protrude far out of the spindle so even big work pieces can be measured. The Zero Master can be read with a small analog dial gauge.

The Sensor is waterproof according to IP 67.

Please take note: The given measuring precision of 0.01 mm only applies if the original HAIMER probe tips are used.

Included in delivery: Zero Master with clamping shank Ø 10 mm, short probe tip Ø 4 mm

Zero Master with clamping shank Ø 10 mm, short probe tip Ø 4 mm

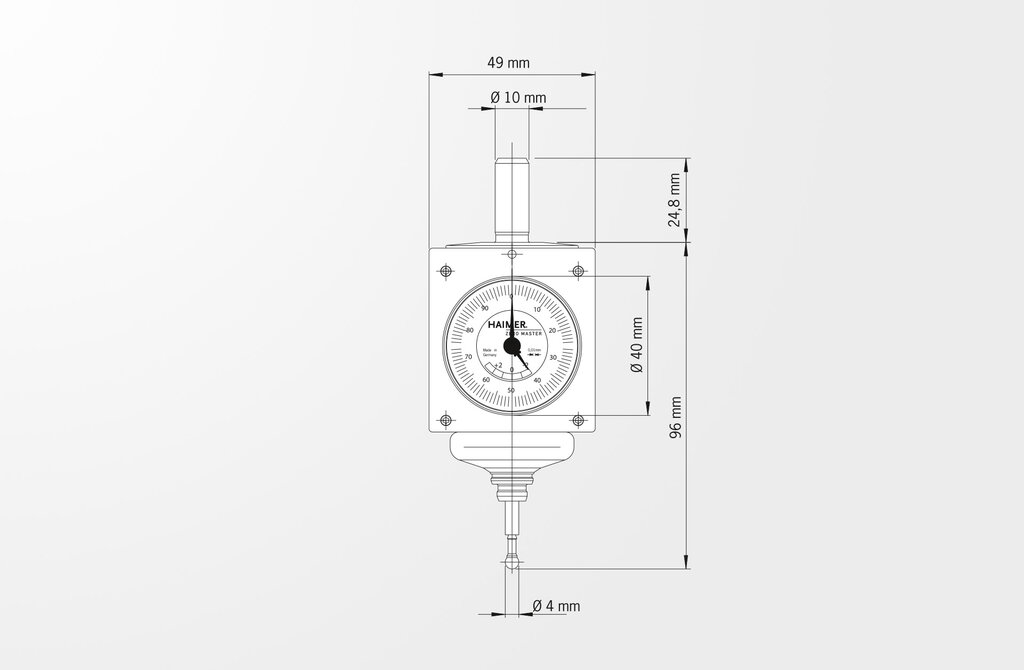

| Description | Norm: | Value: metric/ inch |

|---|---|---|

| Version | Metric | |

| Length 1 | L1 | 96 mm |

| Length 2 | L2 | 24,8 mm |

| Diameter 1 | D1 | 10 mm |

| Diameter 2 | D2 | 4 mm |

| Width | B | 49 mm |

| Smallest unit of measure | 0,01 mm |

- Early wear detection

- Preservation of the target condition

- High availability of HAIMER specialists

- Consistent quality level

- Prerequisite for certification according to ISO 9001